Quality Assurance

Our quality system ensures the highest standards in all phases of production. It includes strictly controlled processes, precise casting parameters, continuous inspections, and non-destructive testing. Our commitment to international standards guarantees consistent product quality and meets the specific requirements of our customers worldwide. This ensures satisfaction and trust in our castings across all industries.

Metallurgy

Our aluminium foundry uses state-of-the-art techniques to monitor metallurgy. Alloy composition is precisely controlled to achieve the desired mechanical properties. Through advanced melting and alloying technologies, we ensure a homogeneous structure and optimal casting characteristics, leading to high-quality aluminium cast products.

Our melt treatment has been developed and refined over many years. The main focuses in our metallurgical department are:

- Melt treatment

- Spectrometer

- Density index

- Thermal analysis

- Microscopy

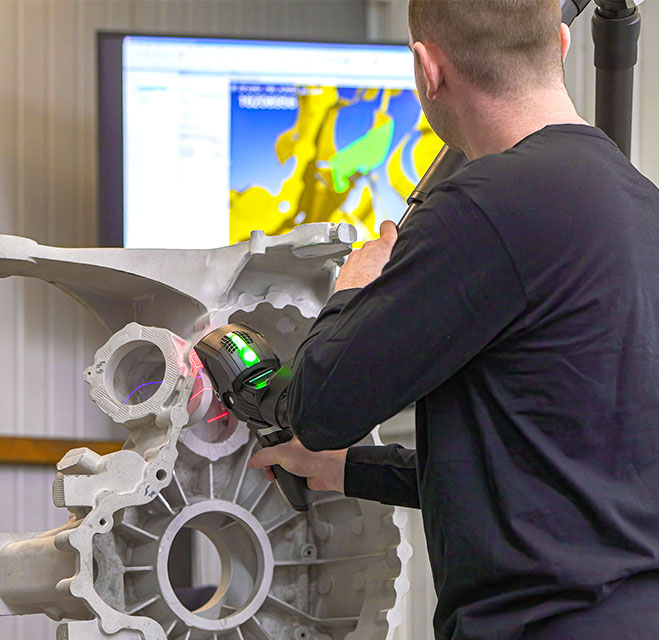

Measuring Technology

Only through measurement can we establish facts and prove the quality of our products. Measurements begin at goods receipt and continue through countless process parameters to the finished component. Measurements require certified measuring equipment and trained personnel. Archiving and analyzing measurement data from previous years provide valuable know-how for continuously improving our production. Measurement technology includes, among others:

- Molding sand analysis

- 3D laser scanner

- CMM measuring machine

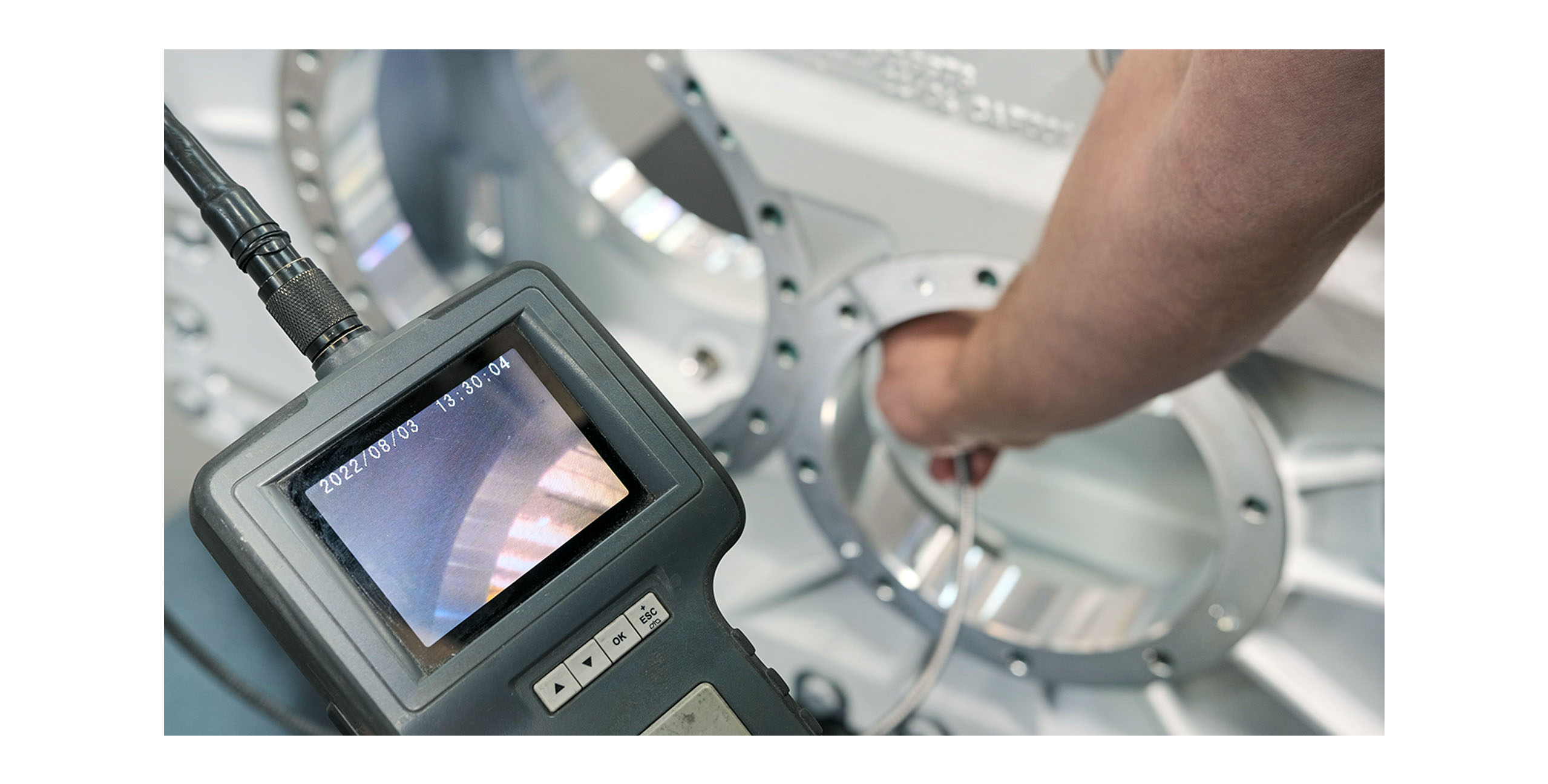

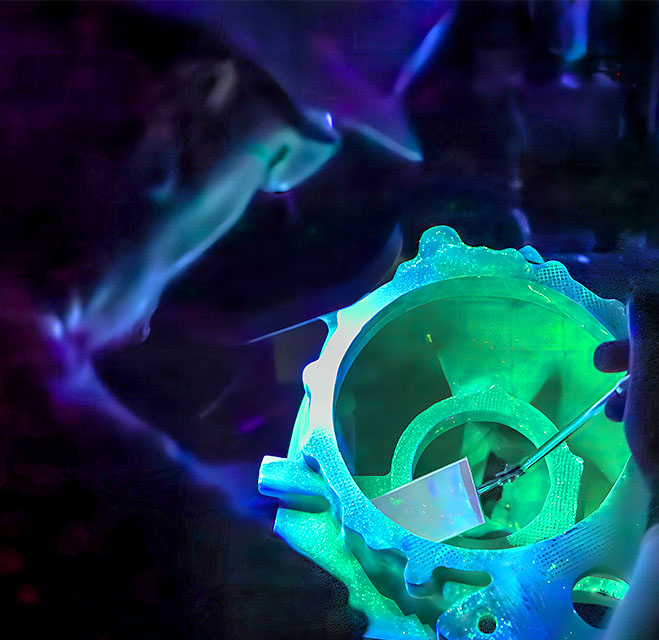

Non-destructive Testing

Our NDT department acts as a service provider for our customers and monitors processes to maintain the highest quality standards. Depending on specifications, our aluminium castings are tested and certified there. The specifications depend on the customer, the region, or the specific industry for which the component is intended.

Various X-ray systems are used, allowing digital and film-based inspection. These tests provide insights into the internal structure of the cast parts. In addition to radiography and digital radioscopy, crack testing is also performed – either using the red-white method or the fluorescence method (FPI). These dye penetrant tests provide information on surface quality and possible cracks in the cast parts. The following additional tests are also carried out on the components:

- Coating thickness analysis (surface coating)

- Pressure and leak tests (water, air and Helium)

- Electrical resistance measurement

- Ultrasonic testing

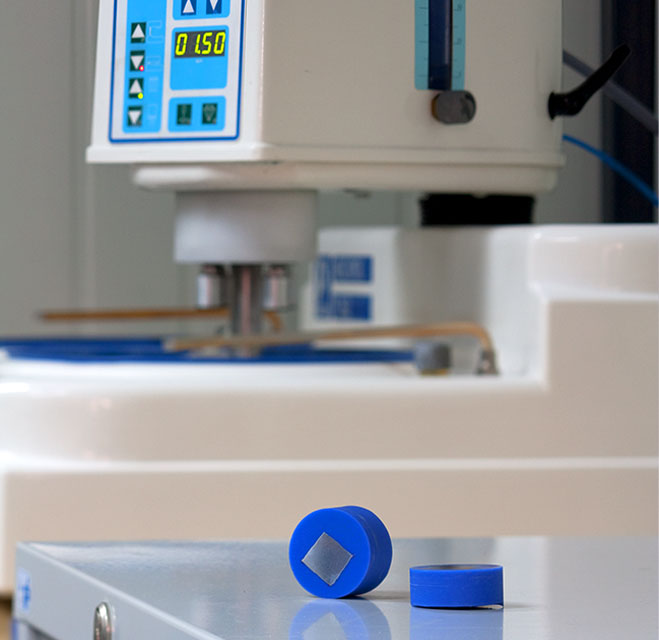

Destructive Testing

In addition to non-destructive tests, destructive tests are also performed. These mainly serve to determine the strength of the castings. In our tensile testing machines, sample bars are destroyed for serial production certification. For the approval of initial samples, castings are cut according to specifications and qualified through the testing of multiple samples.

For pressure-loaded parts, burst tests are also conducted for approval to release the design and production. For running gear components in rail vehicles, vibration tests must be passed. Thoni Alutec offers individual tests tailored to the intended application of the cast parts.