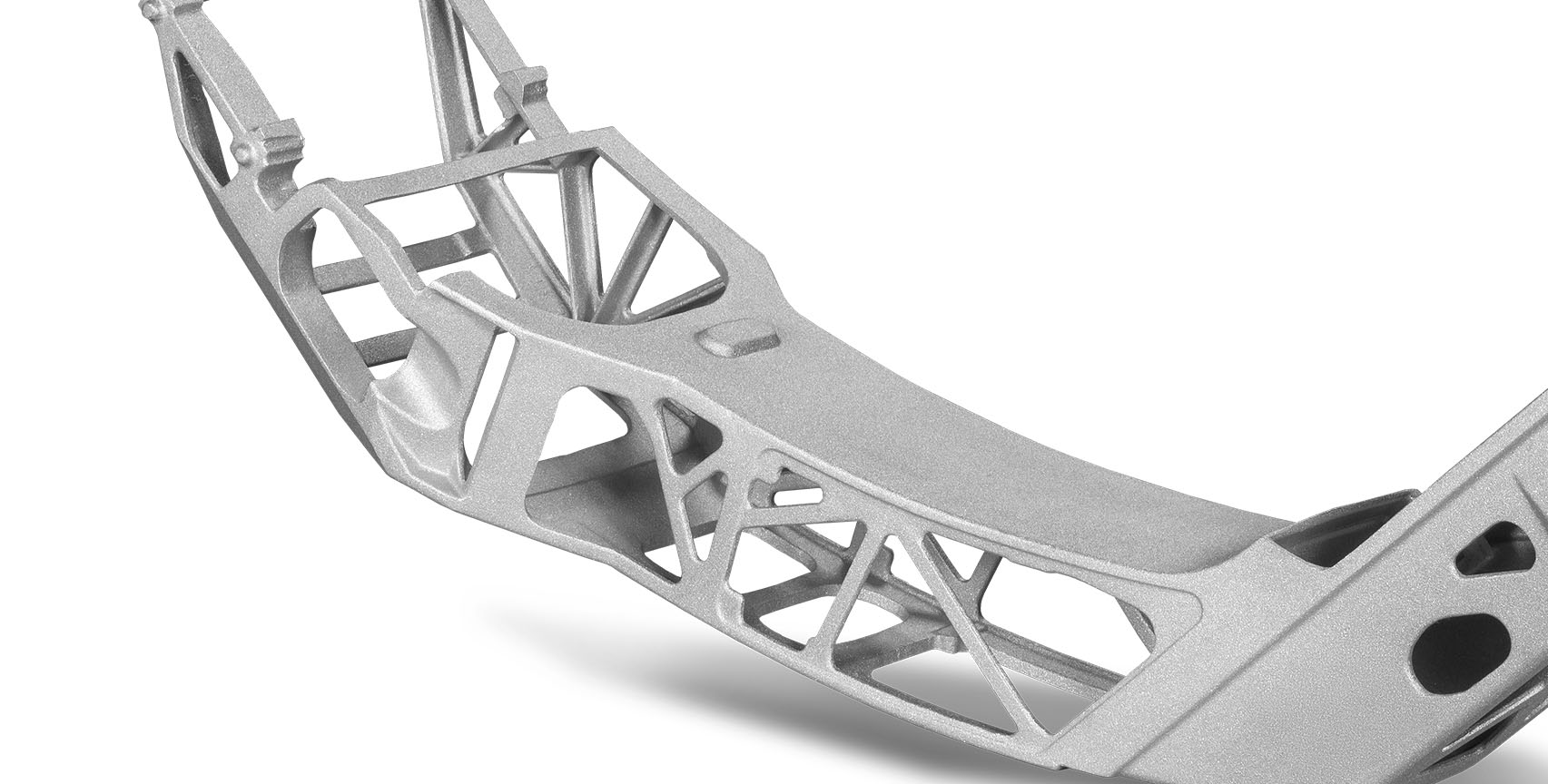

Lightweight construction for limited ceiling loading's

Aluminium casting in medical technology offers an optimal combination of lightness, strength, and formability, which is critical for advanced medical devices. Through precision and versatility, aluminium casting enables the production of highly complex components, ensures compliance with strict hygiene standards, and supports the development of innovative, patient-orientated solutions in the medical industry.

an unbeatable material

In medical technology

The combination of aluminium’s technological properties makes it a clear favorite for device manufacturers in the medical field. Low specific weight, corrosion resistance, strength, and the fact that aluminium is non-magnetic leaves no alternative material choice. Tens of thousands of cast parts from Thoni Alutec are installed worldwide today and help medical professionals heal others.

What properties favour aluminium casting's for medical technology?

- Thermal conductivity

- Corrosion resistance

- Electrical conductivity

- Non-magnetic

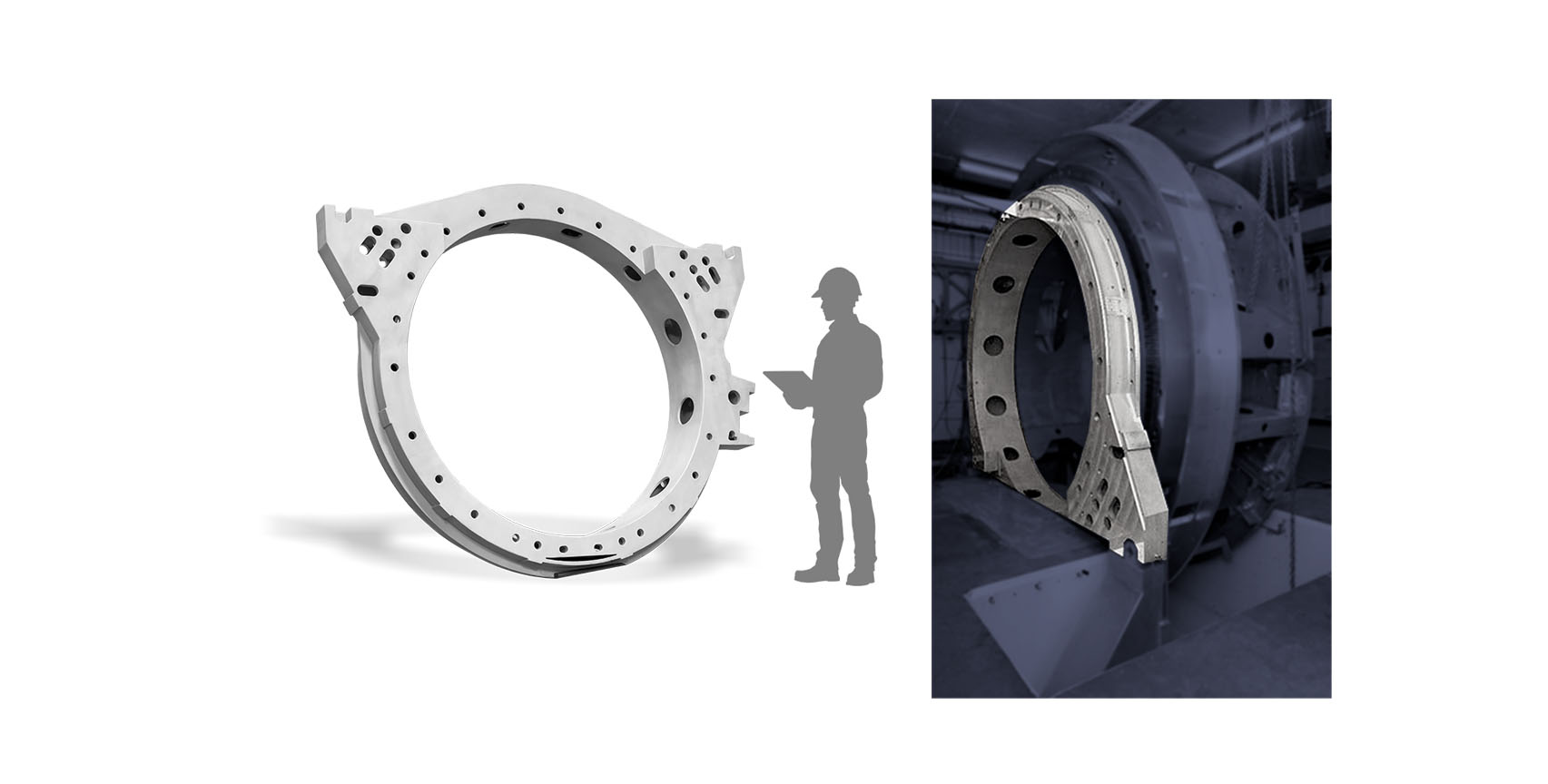

Examples of aluminium casting's

for the medical machinery technology

Examples

- CT scanner

- Patient beds

- X-ray systems

- Lighting

- Treatment chairs

Casting processes Thoni - Alutec offers

for medical technology castings

Casting processes

- Sand casting with the 3D sand printing process (prototypes)

- Sand casting using chemically bonded moulding processes (no-bake process)

- Sand casting on automatic molding line

- Gravity die casting

- Low-pressure die casting

- Low-pressure sand mould casting technology

Got any questions? Or need advice?

Use the form or contact us