OF THE FUTURE

Material of the present and the future

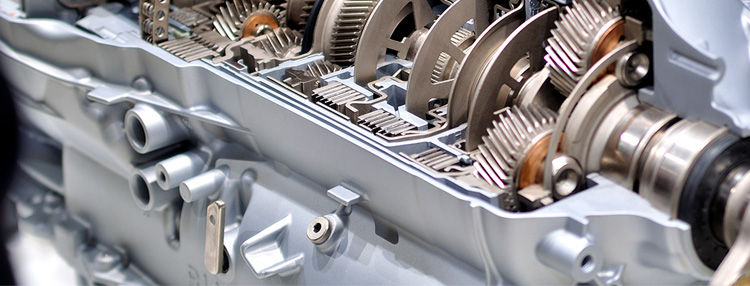

In recent years, the demands in gear manufacturing have increased significantly in terms of competitiveness and cost reduction. Gears must be more robust, powerful, compact, cost-efficient, and above all lighter. This brings aluminum to the forefront as the preferred material, since it is significantly lighter than steel. Weight means cost—especially when gears must be moved during operation.

Every gram counts

Unnecessary weight in the gearboxes of vehicles like cars, construction and agricultural machines, cranes, or ships leads to additional energy consumption. This is where aluminum stands out: with a specific weight of around one-third of that of steel, gearboxes made of an aluminum casting are lighter and save a great deal of energy.

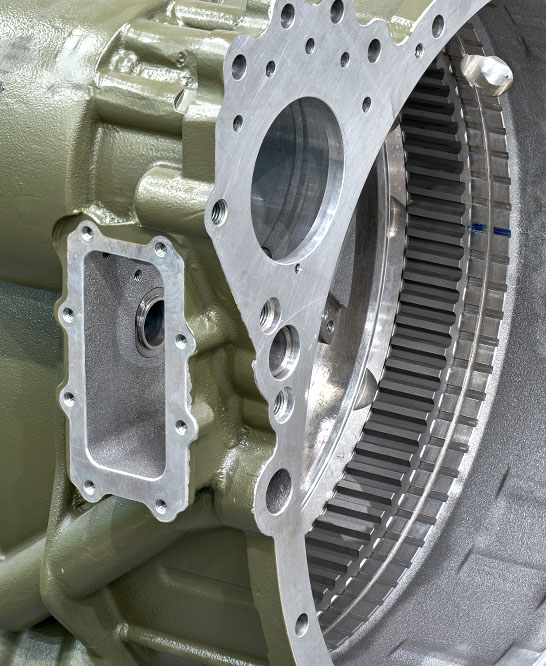

Gear housings typically generate a lot of heat that must be dissipated. Since aluminum has excellent thermal conductivity, aluminum cast gear housings can efficiently and rapidly transfer internal heat to the surroundings. Through the casting process, additional cooling fins can be integrated into the housing to enhance the cooling effect.

What properties promote aluminum castings in gear manufacturing

- Thermal conductivity

- Corrosion resistance

- Low density / weight

- Noise reduction

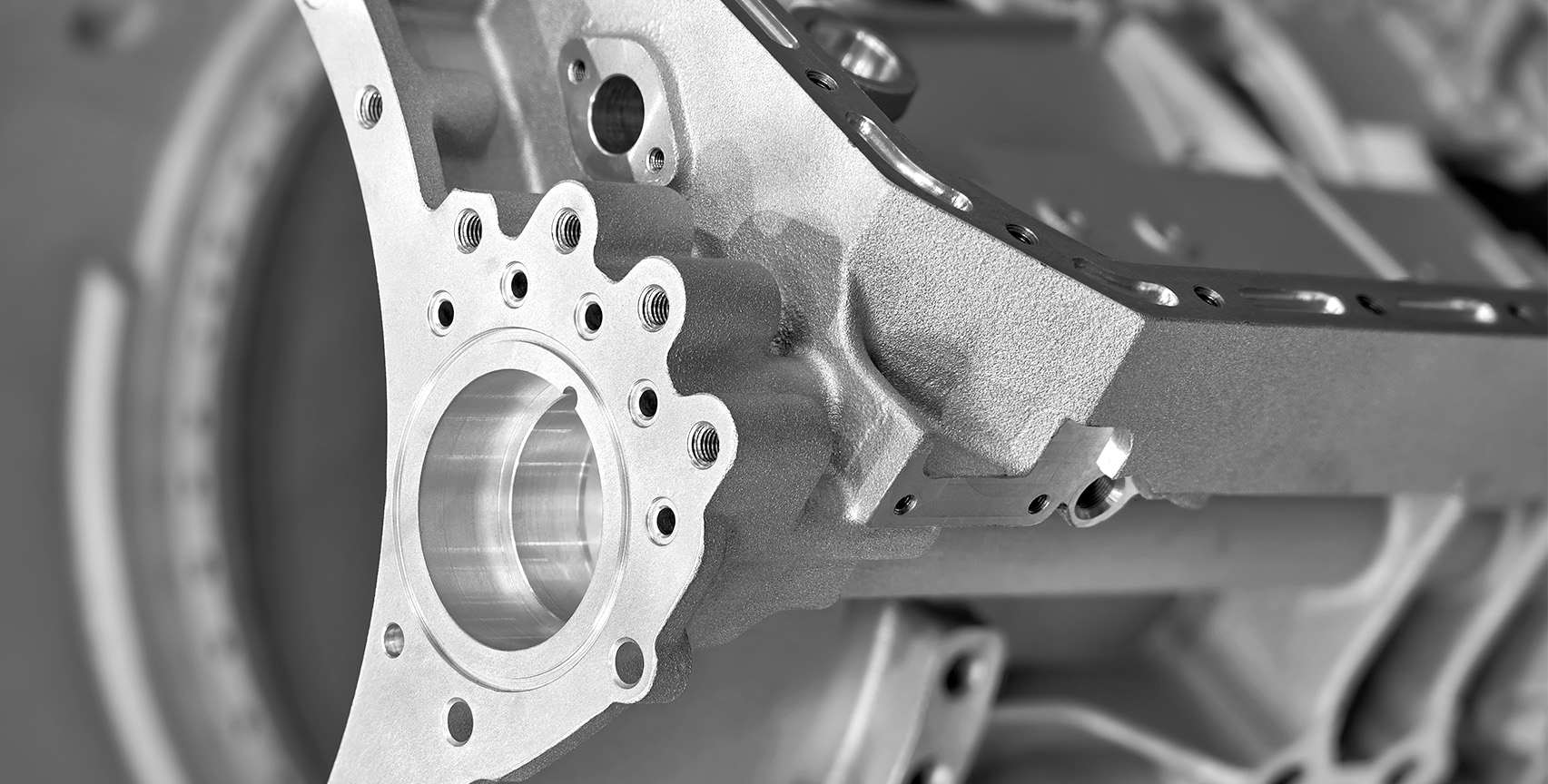

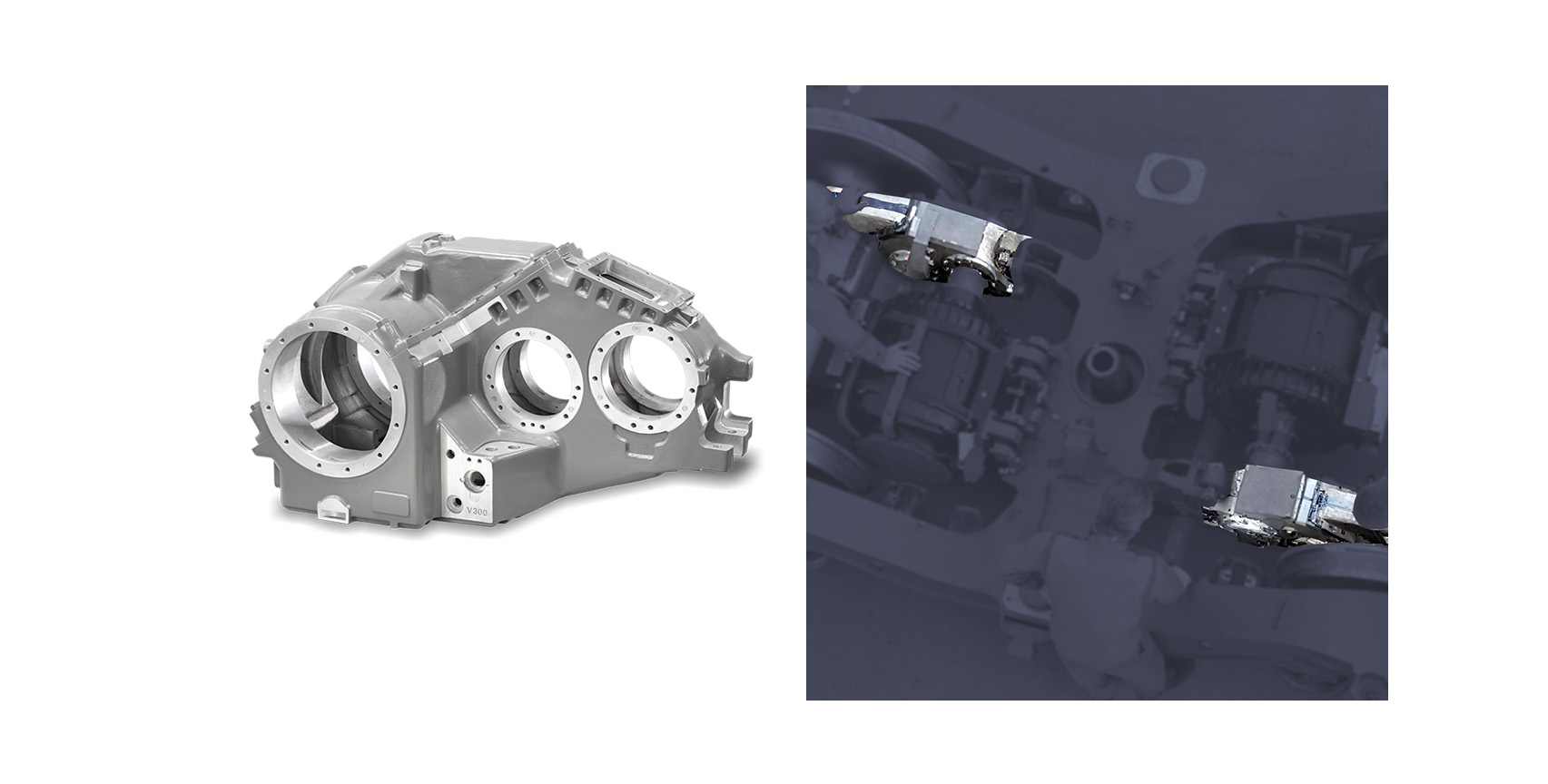

Examples of aluminum casting's for gear manufacturing

Examples- Cranes

- Rail vehicles

- Trucks

- Buses

- Construction and agricultural machinery

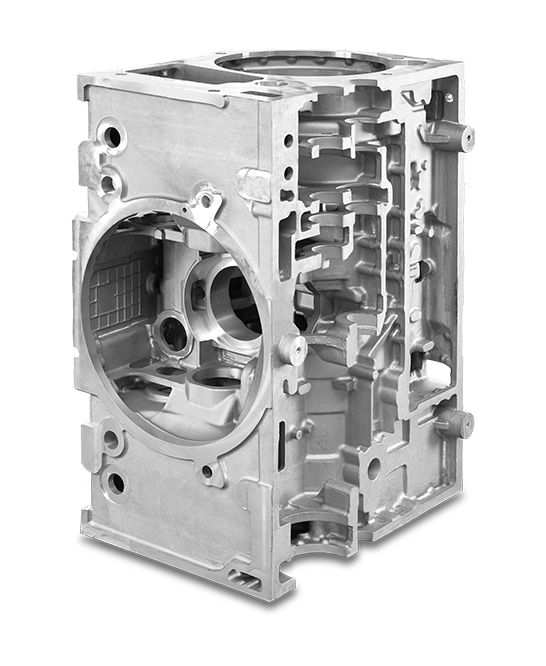

Which casting processes does Thoni Alutec offer for gear manufacturing?

Casting processes- Sand casting with 3D sand printing (prototypes)

- Sand casting using air setting resin molding process's (no-bake process)

- Sand casting with automatic molding line

- Gravity die casting

- Low-pressure die casting

- Low-pressure sand mould casting

Got any questions? Or need advice?

Use the form or contact us