choice

The preferred

choice for energy distribution

In energy distribution, aluminum castings are increasingly used. These systems are installed to supply energy reliably for decades without failure. The cast components are filled with gas or oil to prevent sparking. These parts must be especially gas-tight, pressure-resistant, and protected against high internal pressures. Leaky cast parts could result in critical infrastructure failures and environmental damage.

requirements

Only aluminum meets the technical requirements

Aluminum is corrosion-resistant, ensuring long service life of components in these harsh environments. Due to its high thermal conductivity, any generated heat is effectively dissipated, preventing overheating. Thanks to its high electrical conductivity, aluminum is an ideal material for energy distribution.

What are the advantageous properties of aluminum casting's in energy distribution?

- Thermal conductivity

- Corrosion resistance

- Electrical conductivity

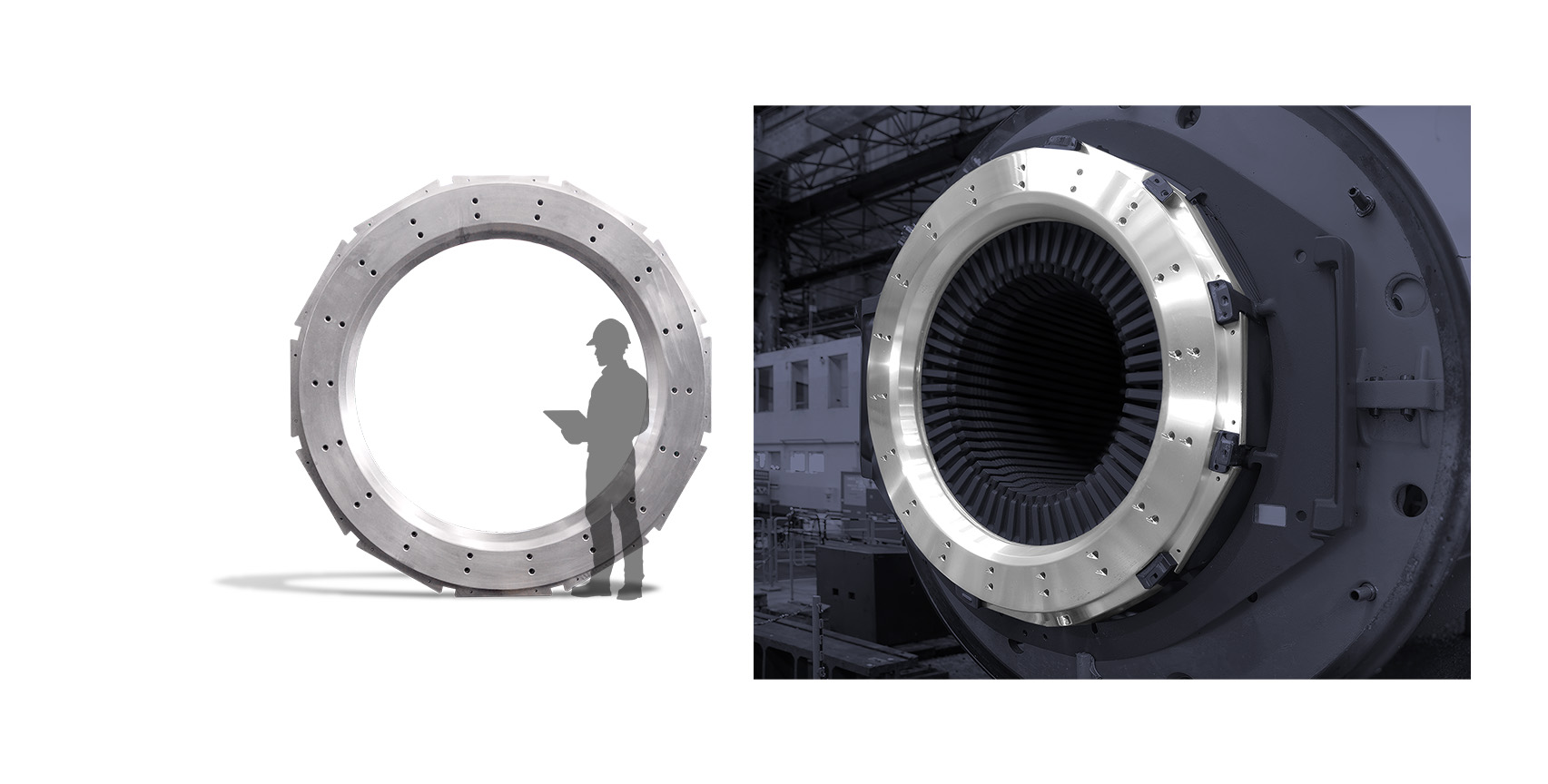

Examples of aluminum casting's

for energy distribution

Examples

- GIS switchgear

- AIS switchgear

- Voltage converters

- Conductors

- Transformers

Which casting processes does Thoni

Alutec offer for energy distribution?

Casting processes

- Sand casting with 3D sand printing (prototypes)

- Sand casting using air setting resin moulding process's (no-bake process)

- Sand casting with automatic moulding line

- Gravity die casting

- Low-pressure die casting

- Low-pressure sand mould casting technology

Got any questions? Or need advice?

Use the form or contact us