Aluminum means lightness

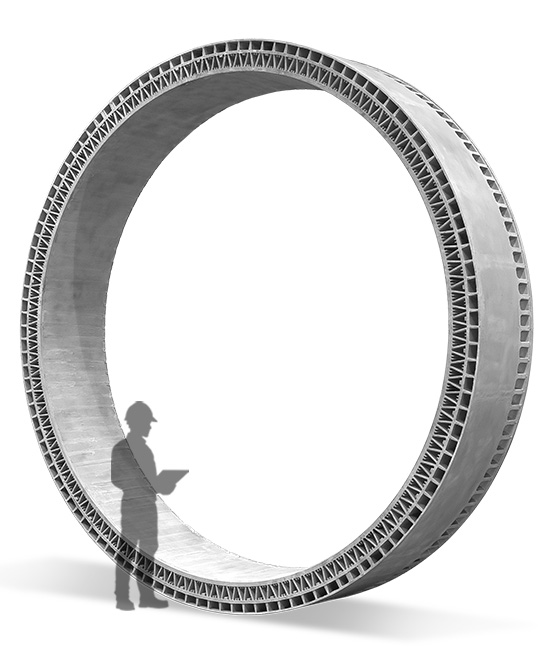

Aluminum is increasingly used in alternative energy applications because it is nearly 70 percent lighter than steel. In wind power systems, components must be installed at great heights. Therefore, every weight saving is welcome, making aluminum a highly sought-after material. Excellent heat dissipation in the rotors automatically increases the efficiency of the systems.

Alternative Energy

Recyclable

100% recyclable aluminum offers true sustainability

Another typical example of aluminum casting is blade tips for the ends of rotor blades, including integrated lightning protection connections. These stabilize rotor operation and reduce noise emissions. The use of aluminum in alternative energy systems fits perfectly with the principles of sustainability, as aluminum is 100% recyclable.

Characteristics

Characteristics

Whatare the advantagous properties for aluminum sand casting's in alternative energy?

- Aluminum casting stands for lightweight design. Low weight saves costs, especially for parts used in wind power systems installed at great heights

- High corrosion resistance leads to longer lifespan and greater maintenance-friendliness

- High thermal conductivity enables optimal heat dissipation

- Non-magnetic, making it ideal for use in gearless wind turbines

Examples of aluminum casting 's

for alternative energy

Examples

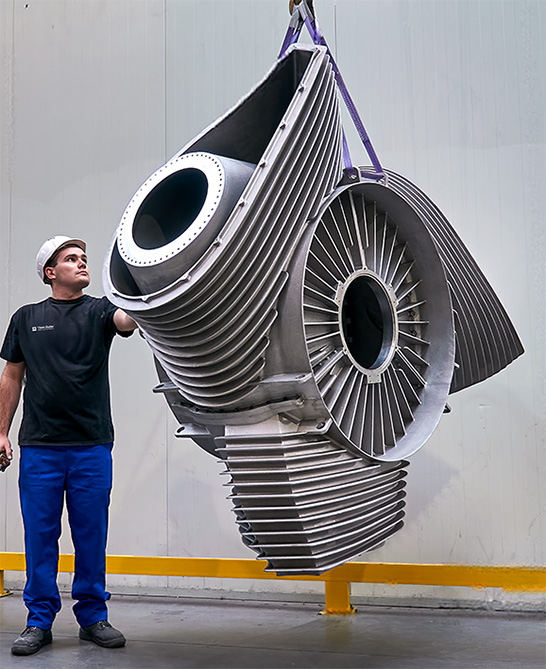

- Rotor

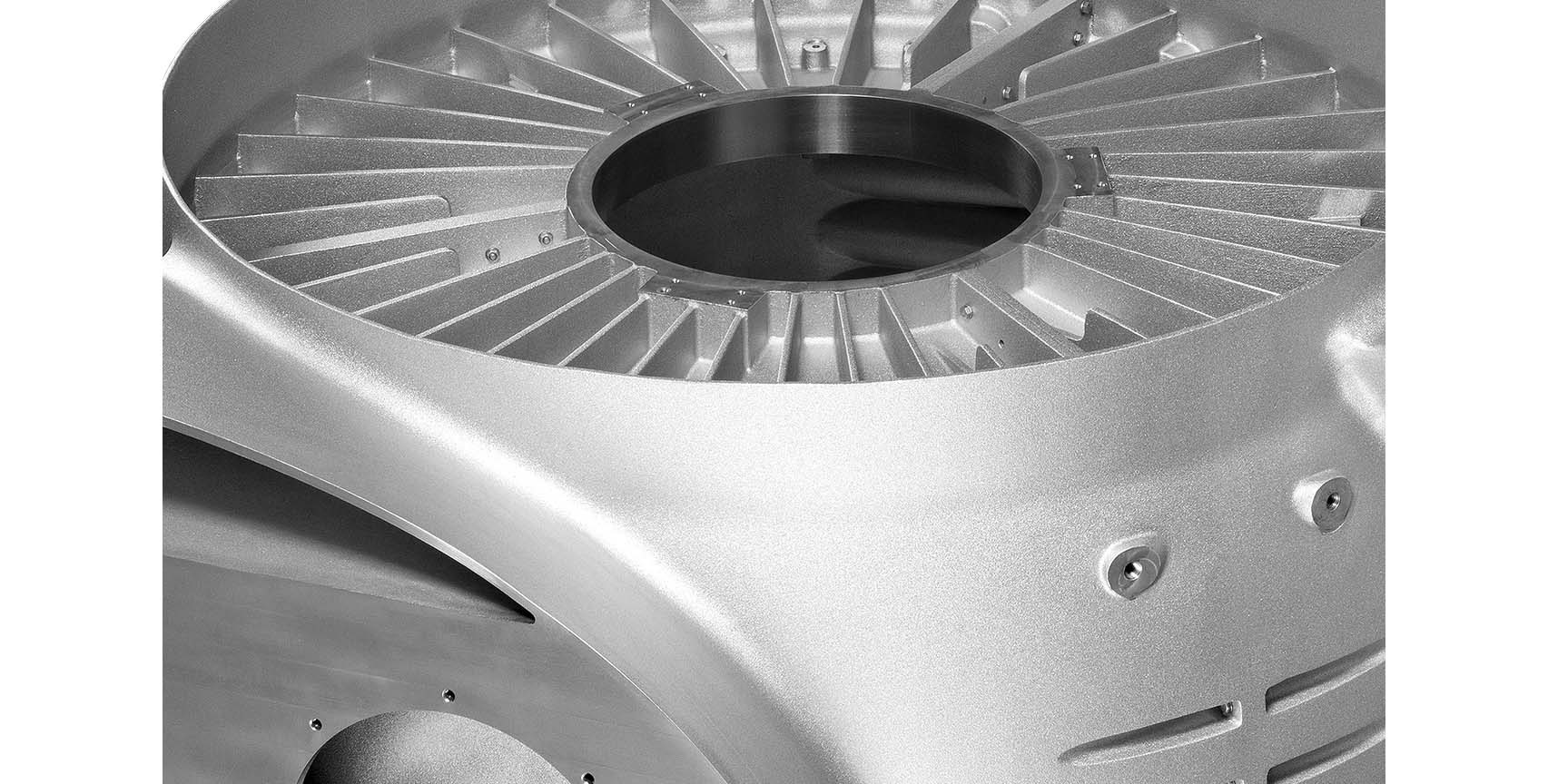

- Generator covers

- Stator

- Tower structures

- Blade tips

- Photovoltaic constructions

- Wind blades

Which casting processes does bietet Thoni

Alutec offer for alternative energy?

Casting processes

- Sand casting with 3D sand printing (prototypes)

- Sand casting using air setting resin moulding process's (no-bake process)

- Sand casting with automatic moulding line

- Gravity die casting

- Low-pressure die casting

Got any questions? Or need advice?

Use the form or contact us