FIRST CLASS

Material of

First Class

Aluminum has tremendous potential in the aerospace industry. Aircraft manufacturers prefer aluminum as a material, as weight always plays a crucial role. In addition to weight, corrosion resistance is another key property that makes aluminum the material of choice in aviation. Magnesium components are also increasingly being replaced with aluminum casting due to its superior corrosion resistance.

Design

Net-shape design using

sand casting technology

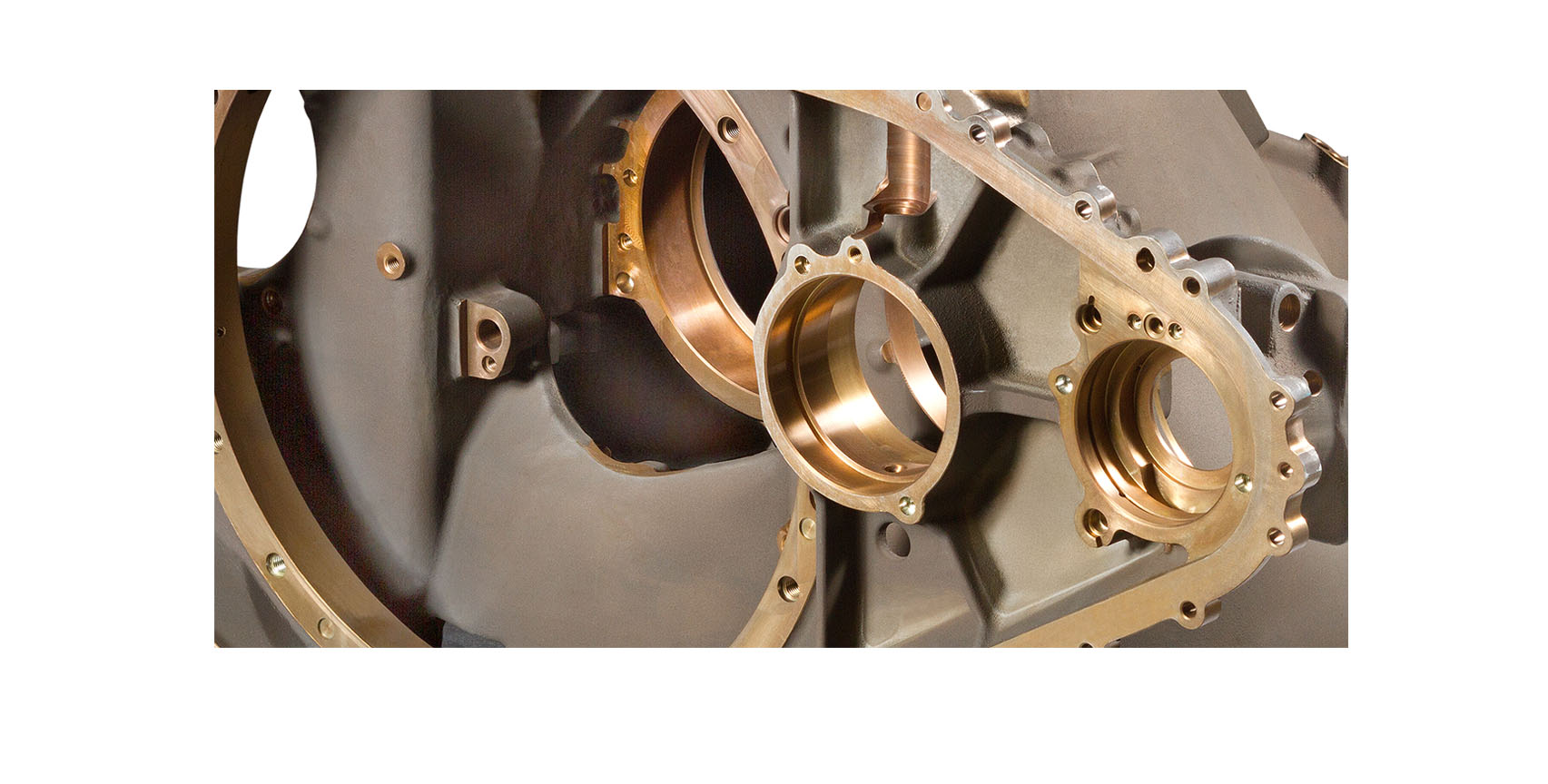

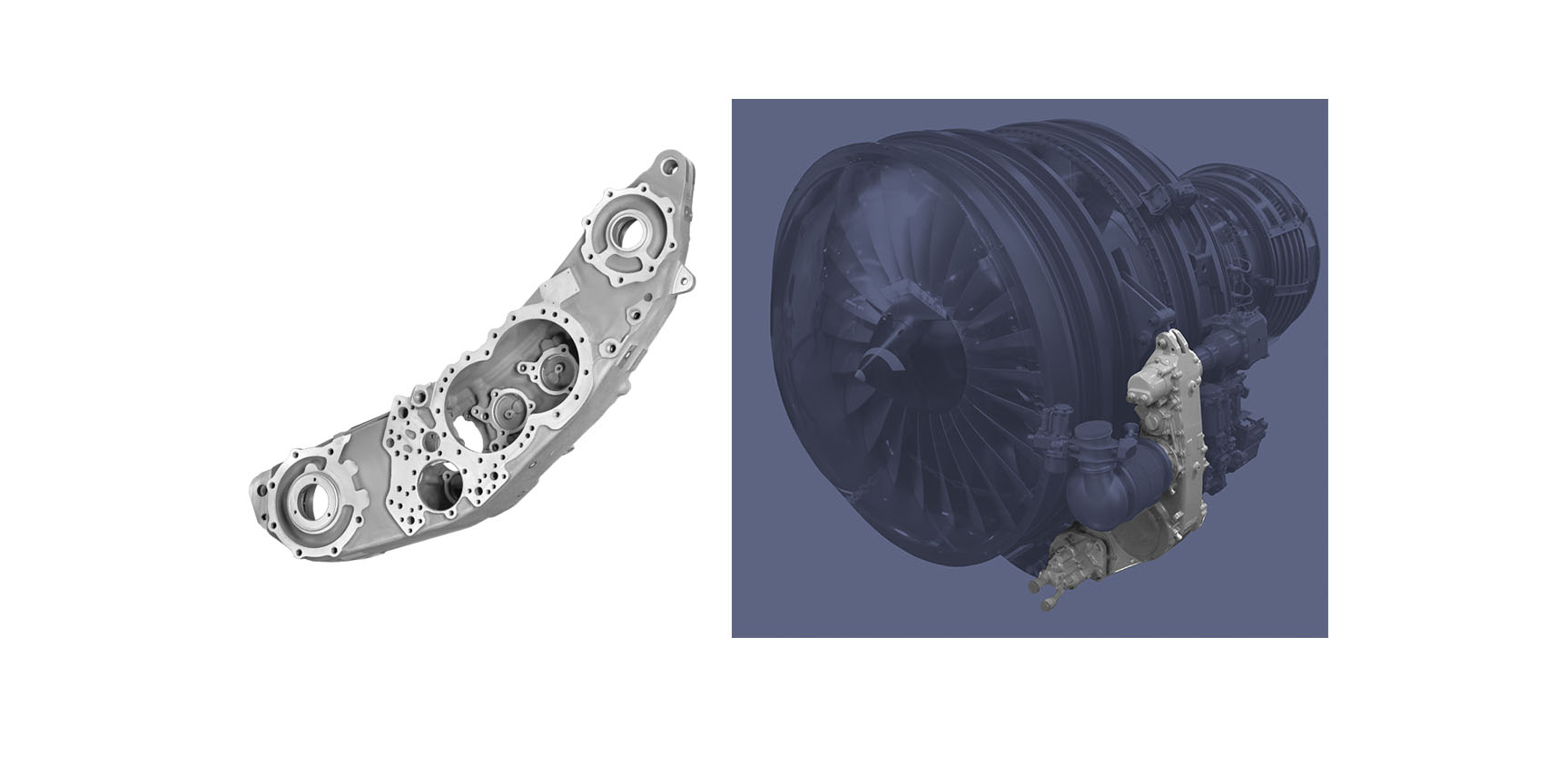

Aluminum offers high strength at low weight and weighs only one-third as much as steel. About 70% of an aircraft’s structure is made of aluminum. When rolled products are used, up to 80% of the material is lost during machining. Casting alloys are primarily used in engine components, where high complexity in shape and design is required. Our sand casting process allows for the integration of even the smallest oil channels into the components.

What are the advantageous special properties in aluminum sand casting's for aerospace Components ?

- Outstanding corrosion resistance increases lifespan and improves maintenance-friendliness

- Aluminum has a significantly better weight-to-strength ratio than steel. Therefore ideal for aerospace use

- Resource-efficient, as it can be completely recycled after use

- Cost savings compared to solid material solutions, which require 80% to be removed by machining

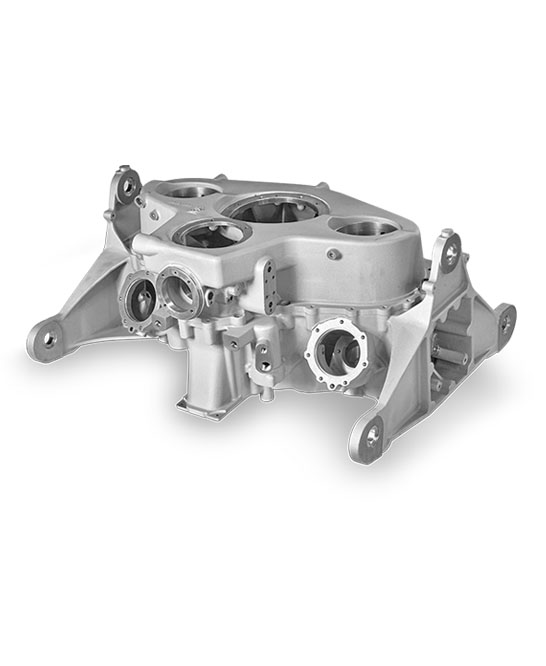

Examples of aluminum casting

in aerospace components

Examples

- Gear housings

- Exhaust systems

Which casting processes does Thoni

Alutec offer for aerospace components ?

Casting processes

- Sand casting with 3D sand printing (prototypes)

- Sand casting using air setting resin molding process's (no-bake process)

- Sand casting with automatic moulding line

- Gravity die casting

- Low-pressure die casting

- Low-pressure sand mould casting technology

Got any questions? Or need advice?

Use the form or contact us