Material

The perfect material

for robotics

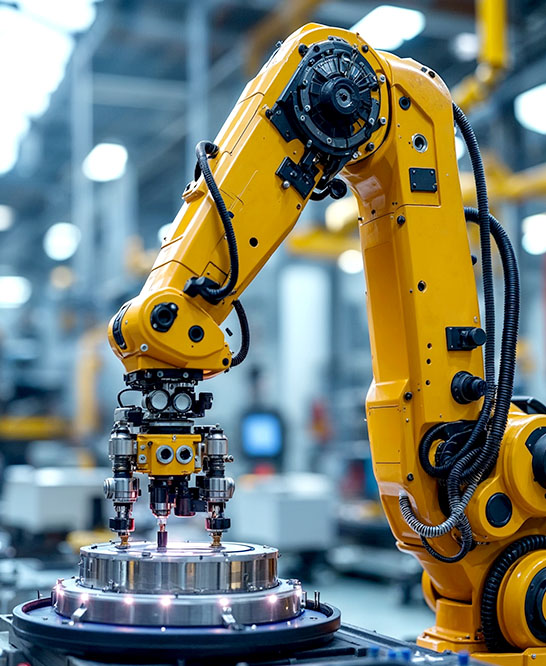

Aluminum meets all the requirements for use in industrial robots. In industrial automation, the focus is on fast and computer-controlled motion sequences. Here, aluminum is the ideal material. It fulfills the high demands for versatility, stability, stiffness, and lightness. This is especially important under the high G-forces of high-performance robots.

Robotics

Lightweight Construction

Lightweight construction for higher load capacity

Modern industrial robots must move quickly to be efficient. Therefore, lightweight construction is essential in robot manufacturing. A typical material is aluminum—a multitasker with many first-class properties and practically predestined for robotics. Intensive use of aluminum can reduce robot weight by up to two-thirds, thus increasing the payload.

Characteristics

Characteristics

What are the advatageous properties for aluminum castings in robotics?

- Aluminum reduces the self-weight of robots

- Aluminum is corrosion-resistant for use in aggressive environments

- Aluminum casting allows robot shapes to be ideally adapted to load requirements based on FEM calculations in the design phase

Examples of aluminum

casting in robotics

Examples

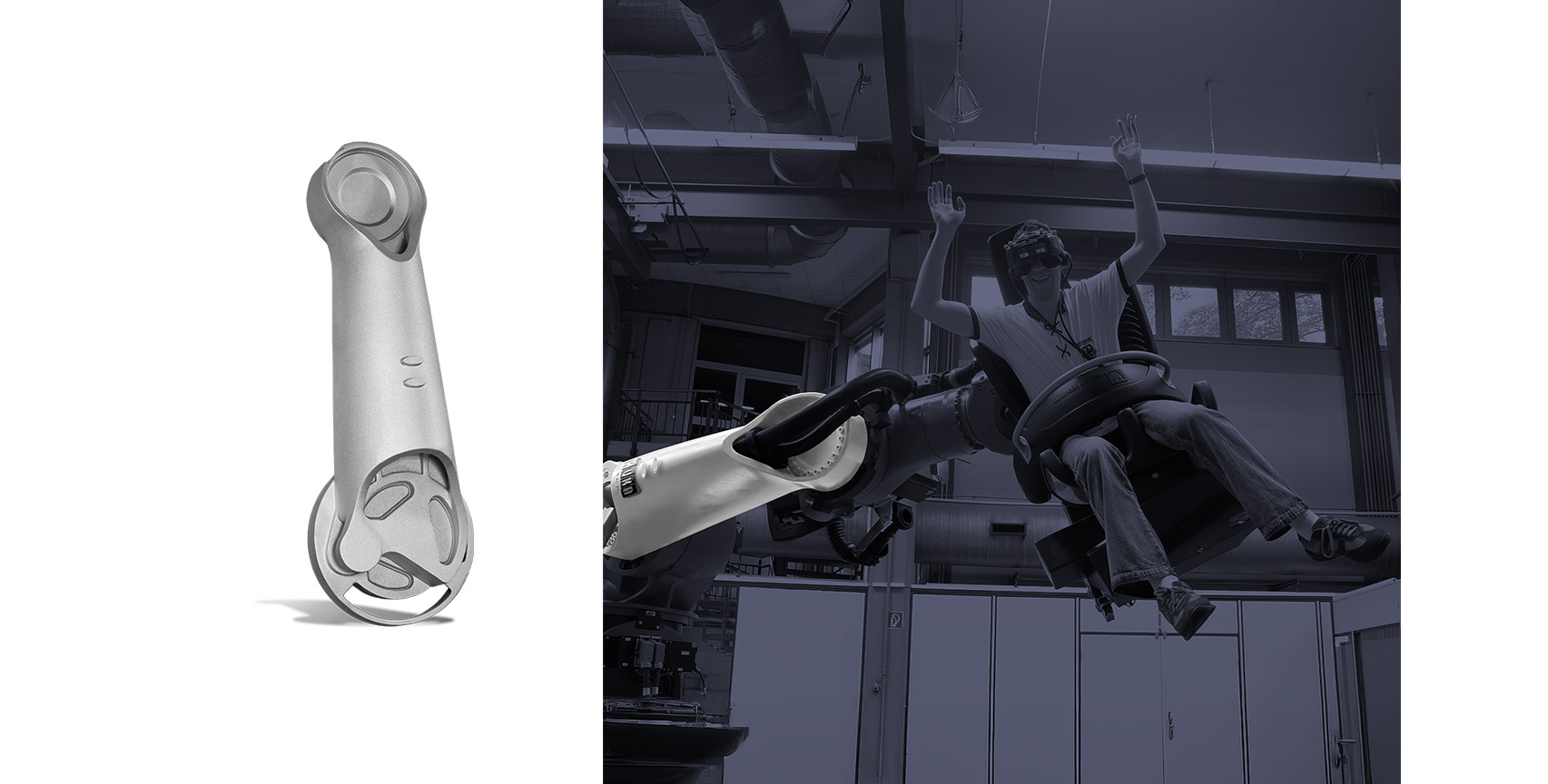

- Arms

- Carousel housings

- AGV platforms

- Swivels

Which casting processes does Thoni

Alutec offer for robotics?

Casting processes

- Sand casting with 3D sand printing (prototypes)

- Sand casting using air setting resin moulding process's (no-bake process)

- Sand casting with automatic moulding line

- Gravity die casting

- Low-pressure die casting

- Low-pressure sand mould casting technology

Got any questions? Or need advice?

Use the form or contact us