Aluminum as an

Industrial Standard

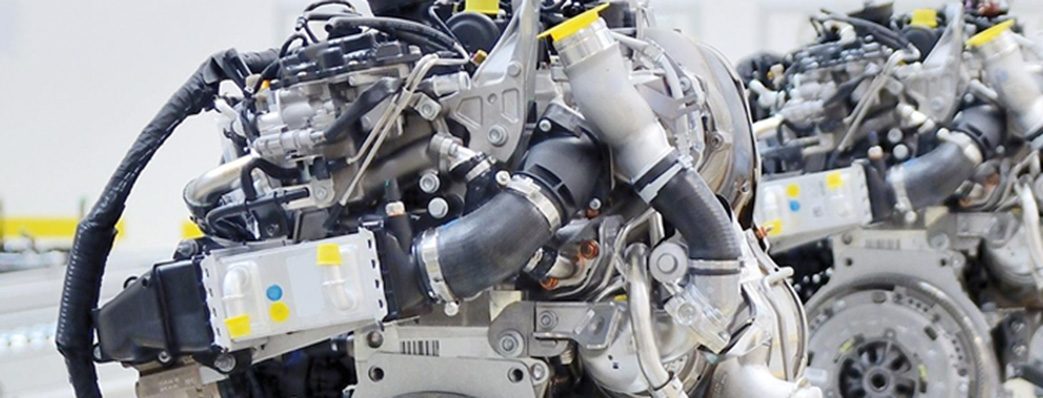

Aluminum casting is indispensable in modern engine construction. The trend in engine manufacturing is increasingly moving towards lightweight construction. This requires materials with low density and high mechanical properties at the same time. An almost ideal material for this is aluminum. Additionally, it offers excellent thermal conductivity, which dissipates the heat generated inside the engine to the environment. It is also possible to cast steel sleeves into the combustion chamber area.

The Motto is Performance

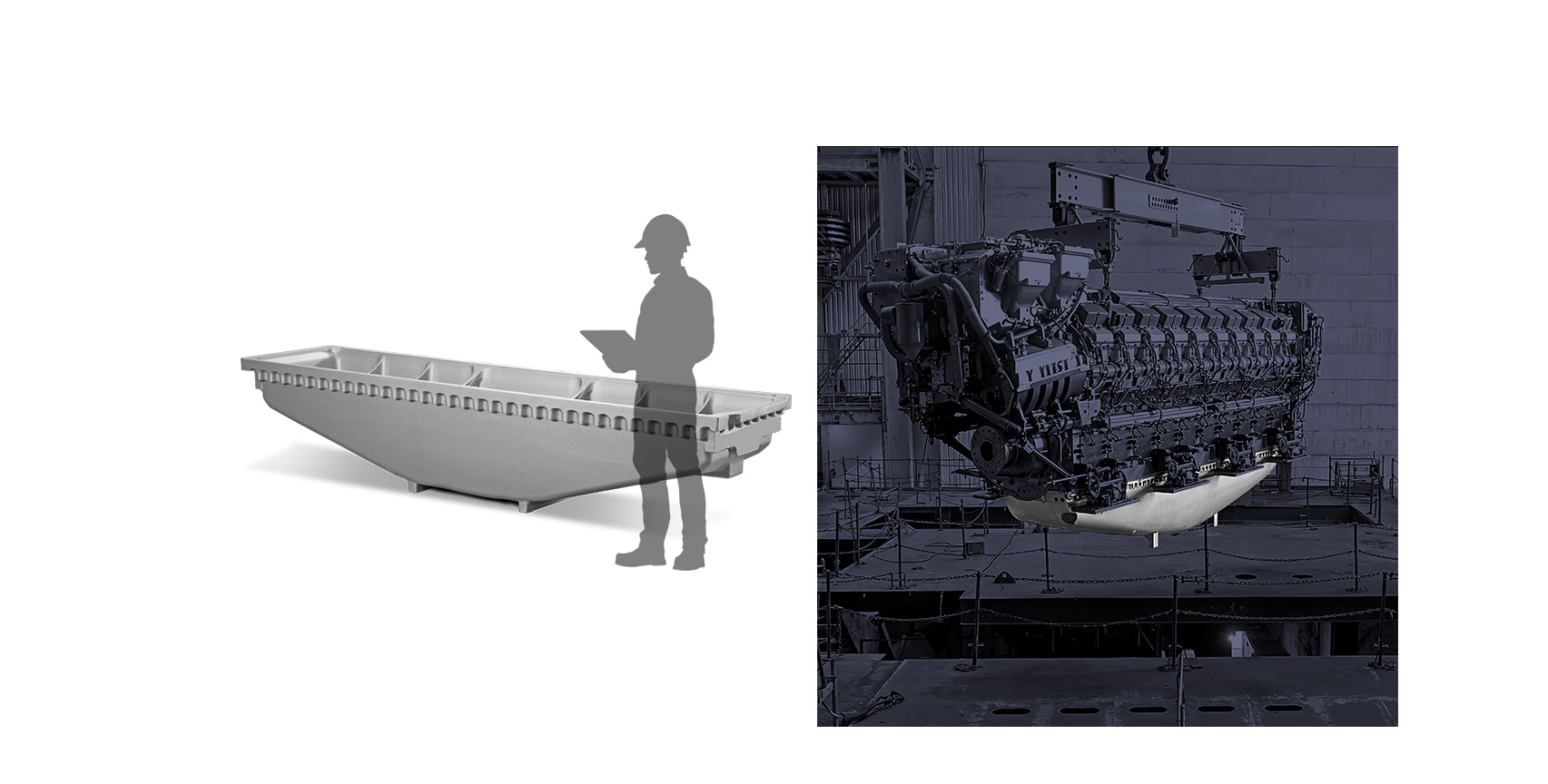

The demands in modern engine construction regarding competitiveness and reduced manufacturing costs are constantly increasing. Engines must be more robust, more powerful, cheaper, and even lighter. As a result, aluminum is moving into the spotlight as the preferred material, since it is significantly lighter than steel. Weight causes costs, especially when engines are installed in mobile vehicles. Large engines are also being produced using advanced aluminum casting technologies.

What are the advantageous properties for aluminum casting's in engine construction?

- Aluminum casting's stands for lightweight construction. Low weight saves costs, especially in engines that are installed inmobile vehicles

- High corrosion resistance leads tolonger service life and high maintenance friendliness

- Optimal heat dissipation through high thermal conductivity

- Conserves resources, as it can be recycled without loss after use

Examples of aluminum casting

in engine construction

Examples

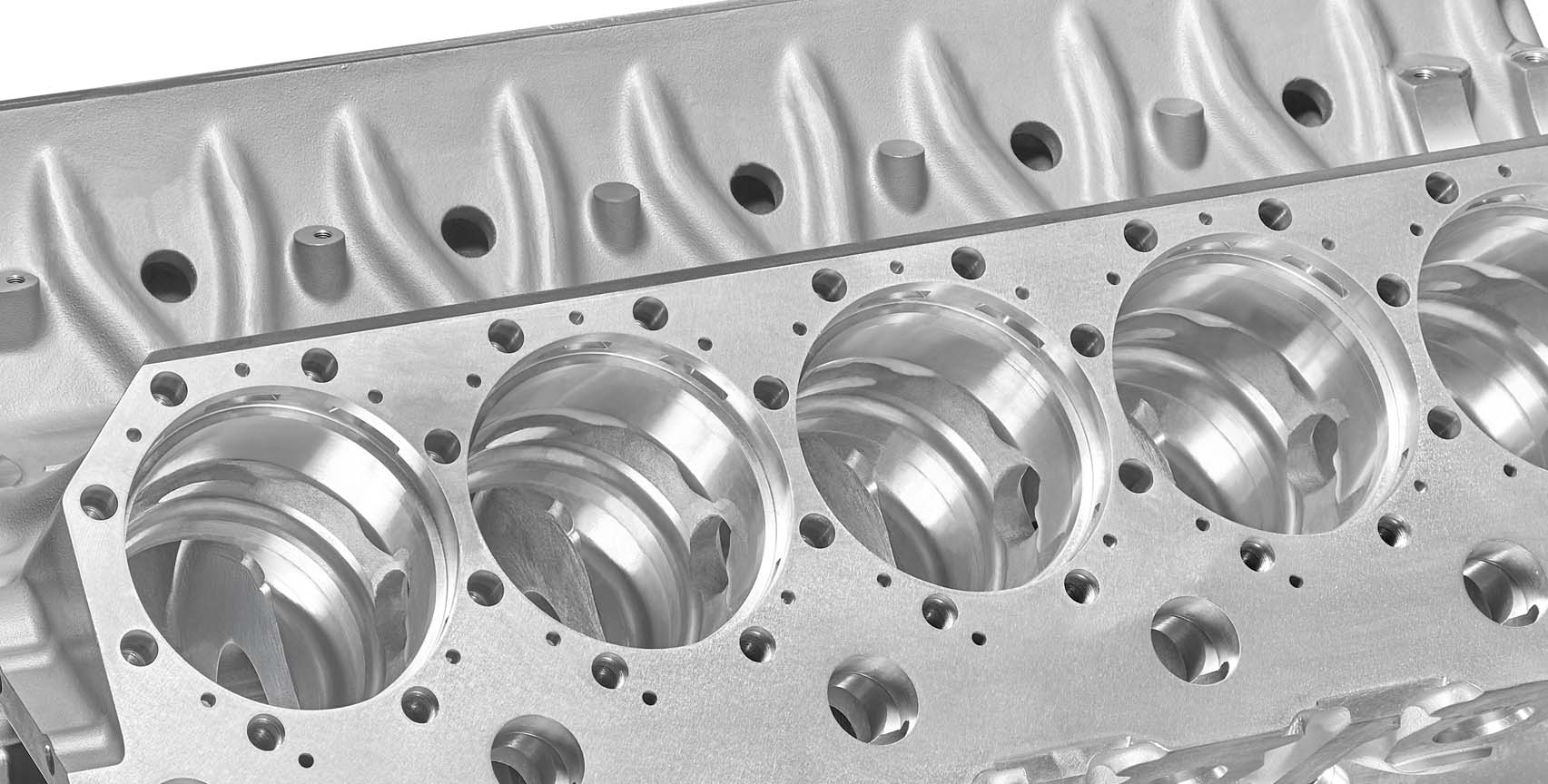

- Cylinder head

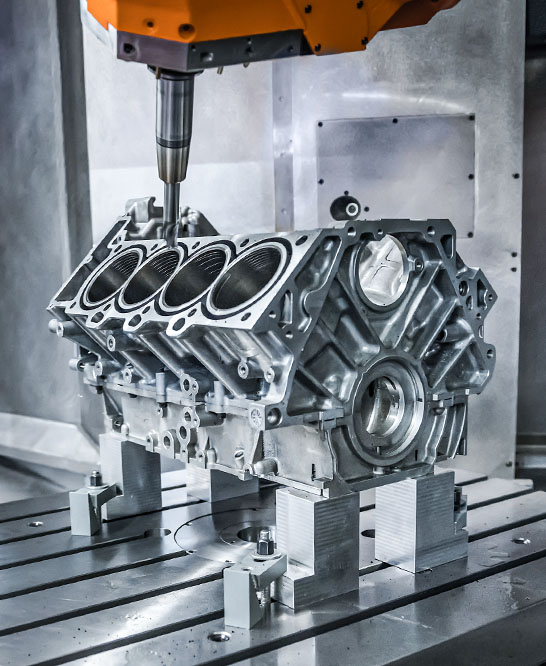

- Crankcase

- Engine block

- Oil pan

- Intake manifold

Which casting processes does Thoni

Alutec offer for engine construction?

Casting processes

- Sand casting using 3D sand printing (prototypes)

- Sand casting using air setting resin moulding process's (no-bake process)

- Sand casting with automatic molding line

- Gravity die casting

- Low-pressure die casting

- Low-pressure sand mould casting technology

Got any questions? Or need advice?

Use the form or contact us