professionals

A team of dedicated professionals

We are a team of dedicated professionals committed to providing our customers with the highest quality aluminum castings. With decades of experience in the foundry industry, we have established ourselves as a reliable and trustworthy partner for all your aluminum casting needs.

Thanks to our state-of-the-art facilities and advanced technology, we can offer a wide range of casting services in sand casting, gravity die casting, and low-pressure die casting. We pride ourselves on our ability to tailor our services to each customer’s specific needs and requirements.

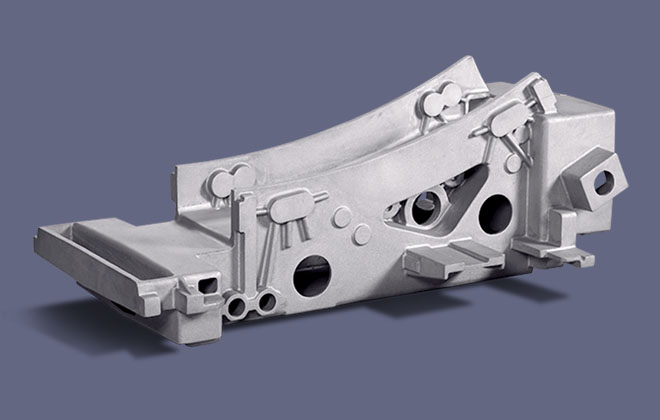

Sand casting using the cold resin molding process

In this process, the molding sand is chemically bonded. Curing occurs through a liquid or gaseous catalyst. It offers impressive flexibility and the ability to create large components. Sand casting creates a destructible, lost mold, which offers considerable freedom in casting design. The process is also known by the following names: no-bake process, furan resin molding process, phenolic resin molding process, cold-box molding process, and PEP-Set molding process.

Advantages of the cold resin molding process

-

Low tool costs

-

Large dimensions

-

High unit weights

-

Production of small annual quantities

-

High design freedom

Typical annual quantities: 20 – 2000 pieces

Typical casting weights: 30 – 3000 kg

Sand casting using the wet casting process

Here we use a fully automated molding system with the Seiatsu process, also called the airflow press process.

Mold production is carried out using a two-stage mold compaction process for bentonite-bonded mold material, which involves pre-compaction in an air stream and final compaction by pressing. This process is fully automated and ensures a homogeneously compacted mold. Our molding boxes measure 1500 x 1050 mm. We recommend this process for components with suitable dimensions and for larger quantities.

Advantages of the wet casting process

-

High accuracy

-

Consistent surface quality

-

High design freedom

-

Low draft angle

Typical annual quantities: 300 – 20,000 pieces

Typical casting weights: 10 – 120 kg

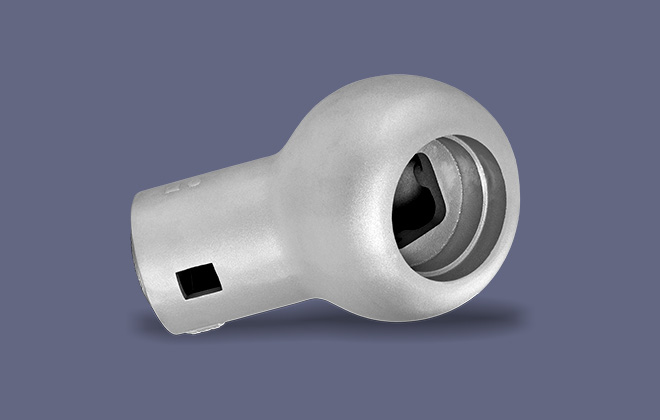

Schwerkraft Kokillenguss

In this casting process, a permanent steel mold is filled from above by gravity. The rapid cooling rate of the aluminum in the steel mold results in high mechanical properties in the casting. The surface quality also exceeds that of sand casting. In gravity die casting, sand cores can also be used to create cavities.

Advantages of gravity die casting

-

High surface quality

-

Lower production costs

-

High strength

Typical annual quantities: 1,000–20,000 pieces

Typical casting weights: 5–25 kg

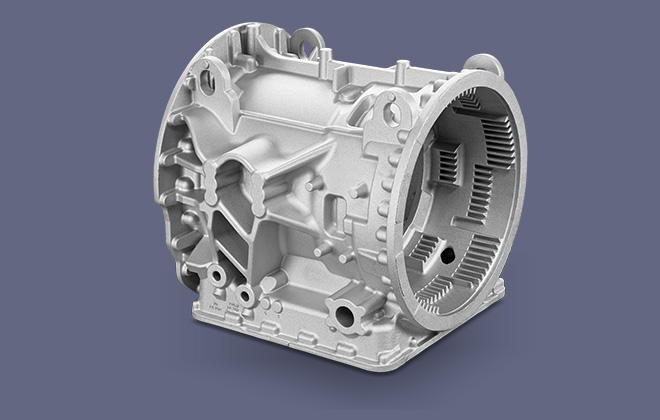

Low-pressure die casting

Low-pressure casting is a further development of the gravity die casting process. Low-pressure casting enables automated and therefore controlled filling of the die from below. The rising, laminar flow of the liquid aluminum alloy results in even higher casting quality and strength.

Advantages of low-pressure die casting

-

Improved casting quality

-

High surface quality

-

Lower porosity

-

Lower unit costs

Typical annual quantities: 1,000–30,000 pieces

Typical casting weights: 15–250 kg

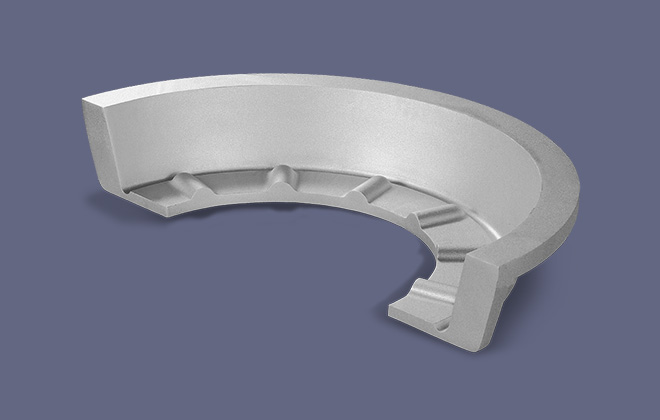

Vacuum forming process (V-Process)

This process is ecologically unique because it uses neither chemicals nor water. The molding material is bonded solely by a vacuum and is 100% recycled. The vacuum forming process is also unbeatable in terms of surface quality and precision.

Advantages of the vacuum process

-

Superior surface

-

Almost no draft angle required

-

Extremely environmentally friendly

Typical annual quantities: 100 – 10,000 pieces

Typical casting weights: 10 – 100 kg

3D sand printing process

For prototypes or individual parts in the service sector, our 3D sand printing process is our customers’ preferred choice. Dimensions are virtually unlimited. 3D printing underscores the motto “time is money” and offers immense savings thanks to its rapid implementation. We also offer core printing for large-scale production.

In the so-called job box, quartz sand with a thickness of 0.2 mm is layered fully automatically. The control system processes the 3D data we create and prints the desired shape by selectively wetting the individual sand layers with resin and hardener. After these regions have hardened, the desired shape is created.

Advantages of the 3D sand printing process

-

Short delivery time

-

Near-series process

-

Production of contours that cannot otherwise be demolded (e.g. oil cores)

-

Low one-off costs

-

Almost unlimited design freedom

Typical annual quantities: 1–10,000 pieces

Typical casting weights: 5–500 kg

Got any questions? Or need advice?

Use the form or contact us