Turning, milling, measuring... aluminum casting in the next step of our supply chain

We offer machining of aluminum castings with the highest precision using state-of-the-art equipment in all dimensions. Our machinery has grown along with our foundry, allowing us to machine all cast parts in-house. This allows us to be independent and flexible, enabling us to handle demanding projects for our customers from a single source for decades.

CNC Turning

In our machining department, our raw castings undergo further processes. This includes machining with CNC lathes.

In this department, we have high-precision CNC lathes specifically configured for machining aluminum castings. Our machine park is very broad in scope to meet the individual requirements of our customers.

We use horizontal lathes with tool magazines, as well as vertical turret lathes for larger components. Turning is often the first step before CNC milling.

The use of CAD/CAM software to create and optimize machining programs allows us to create increasingly efficient machining processes.

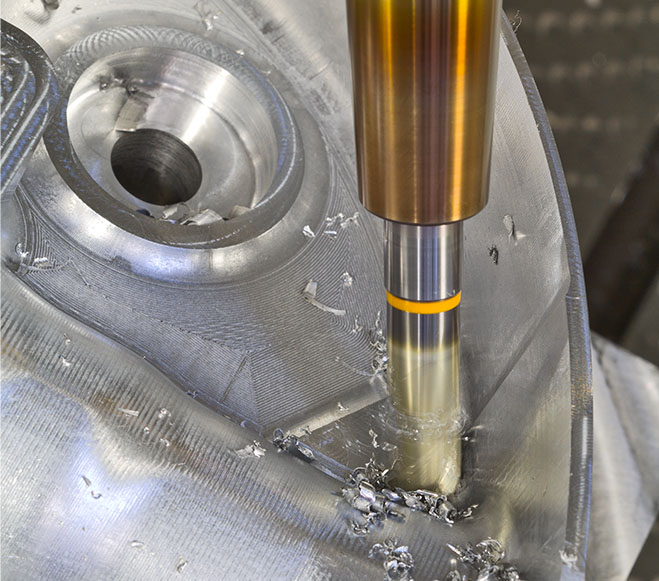

CNC milling

CNC milling accounts for the largest share of our mechanical production. Here, too, we rely on a wide range of machine tools to meet the market’s needs.

From simple 3-axis milling machines to 4- and 5-axis machining centers and even integrated 6-axis turning-milling machines, we always offer a complete solution for our customers.

The machine tools are supplied with tools from a central warehouse via AGVs.

The disposal of our chips is handled by suppliers of our aluminum alloys, thus creating a closed recycling loop.

This department plays a crucial role in our company’s value chain. Efficiency, precision, and quality assurance are of central importance.

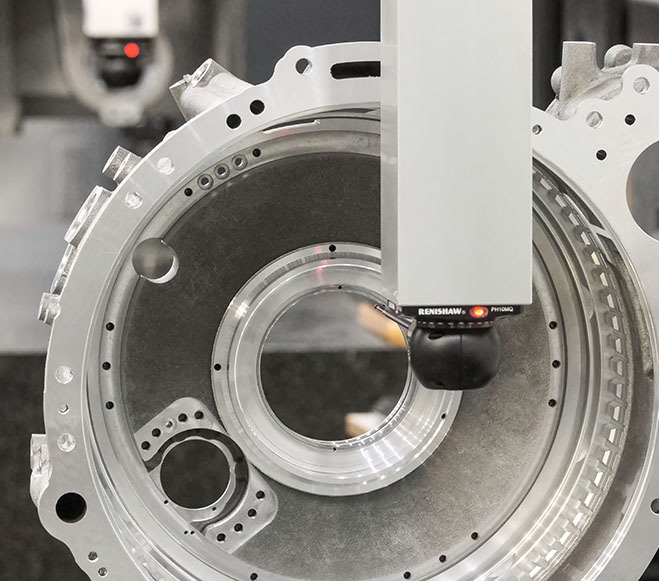

CMM Department

Our CMM department is equipped with the latest metrology equipment. In climate-controlled rooms with temperature locks, we ensure that the measurement process fully complies with our customers’ specifications.

The metrology department is divided into several locations within production, each adapted to the size of the components manufactured there. These short distances enable timely communication between production and the metrology department, even directly at the workpiece if necessary.

Measurements are performed using CMM measuring machines and laser scanners.

In addition to preparing initial sample measurement reports, this department primarily monitors compliance with tolerances during the process.

Got any questions? Or need advice?

Use the form or contact us