Coatings from colorful to electrically conductive.

Our surface coating department offers a wide range of coating processes, ensuring that components receive the desired surface properties and protective coatings. The combination of internal and external processes ensures that aluminum castings meet customers’ specific requirements regarding protection, aesthetics, and functionality. Coating is carried out according to customer specifications and international standards.

Surface preparation

Before the actual coating process begins, thorough surface preparation is crucial. This can be done chemically or mechanically:

- Chemical preparation: This involves cleaning and pretreating the castings using chemical baths or treatments to remove contaminants, oxide layers, and grease. Typical processes include degreasing, pickling, and passivation.

- Mechanical preparation: Mechanical methods such as grinding, sandblasting, or shot blasting are used to clean and roughen the surface to improve the adhesion of the coatings.

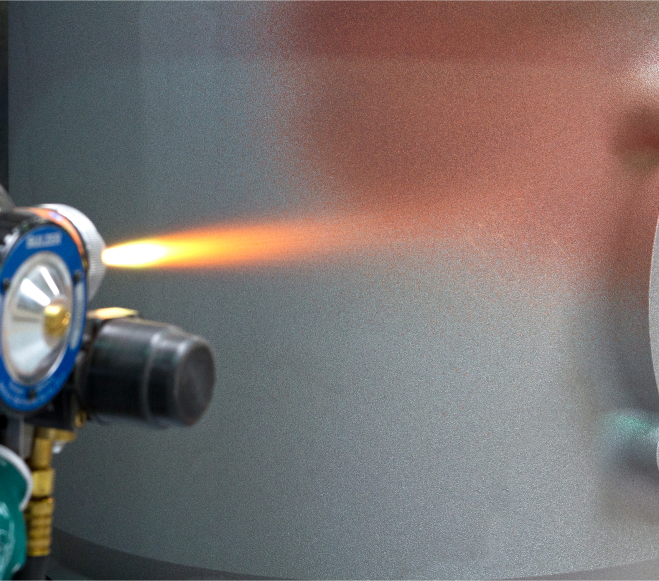

Wet painting with water-soluble paint and 2-component paint

- Water-based paint: This environmentally friendly paint uses water as a solvent and is applied to the prepared parts in a spray booth. After application, a drying phase follows in a drying oven.

- Two-component paint: This consists of two components, a basecoat and a hardener, which are mixed shortly before application. These paint systems are particularly robust and chemical-resistant. They are also applied by spraying and then dried or cured.

Powder coating

Powder coating is a widely used process for aluminum components because it provides a uniform and durable coating. The powder coating is electrostatically sprayed onto the prepared surface. The coated parts are then heated in an oven, which melts the powder and forms a smooth, durable coating.

Slip coating

Anti-friction coatings are applied to improve the friction properties of surfaces. The anti-friction coating is applied by spraying, dipping, or brushing. This coating offers high wear resistance and good sliding properties, ideal for moving parts.

Tampon silver plating

This process is used to coat aluminum parts with a thin layer of silver. A pad impregnated with silver salt is rubbed over the aluminum surface, creating a silver coating. This process enables precise and selective plating of electrical contact surfaces.

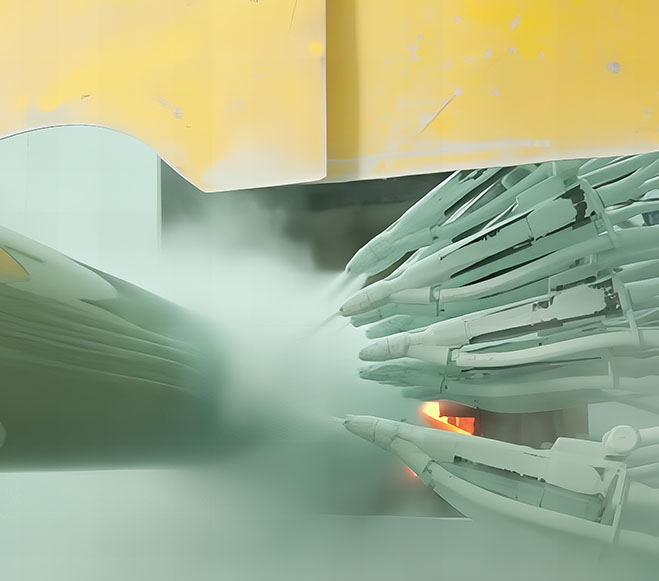

Copper spray plating

Copper spray plating is used to apply a copper layer to aluminum parts. After surface preparation, copper wire is melted in a spray gun and sprayed onto the surface. This method produces a robust and uniform copper layer. Copper spraying is used to create highly electrically conductive coatings.

Eloxal (anodization)

This electrochemical treatment creates a hard and corrosion-resistant oxide layer on the aluminum surface. This is a purely technological coating to protect the cast parts and creates a gray appearance. It primarily provides protection against damage such as scratches and further improves corrosion resistance.

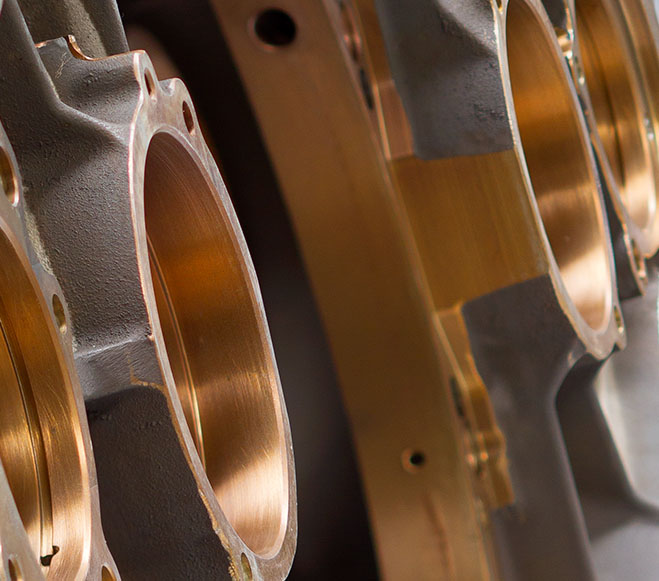

Hartcoat

A special form of anodizing that creates particularly hard and thick oxide layers to maximize wear resistance. Hart-Coat forms a very strong bond with the component, resulting in extremely high surface resilience. Thermal insulation, sliding properties, hardness, and corrosion resistance are significantly improved.

KTL coating (cathodic dip coating)

This process creates a uniform, corrosion-resistant coating through the electrolytic application of paint in a dip bath. It is characterized primarily by its excellent resistance to acids, fuels, and other chemicals. To ensure good adhesion of the e-coating, a passivation process is usually performed prior to application.

Got any questions? Or need advice?

Use the form or contact us