Worldwide

popular

Globally, the construction sector (building and civil engineering) is the number one consumer of aluminum with 25 percent. The reasons are obvious. Aluminum has excellent forming properties and high load-bearing capacity. In building and civil engineering, weight savings, stability, and corrosion resistance are essential properties required of materials.

Architecture

NEW PATHS

Casting processes open new paths

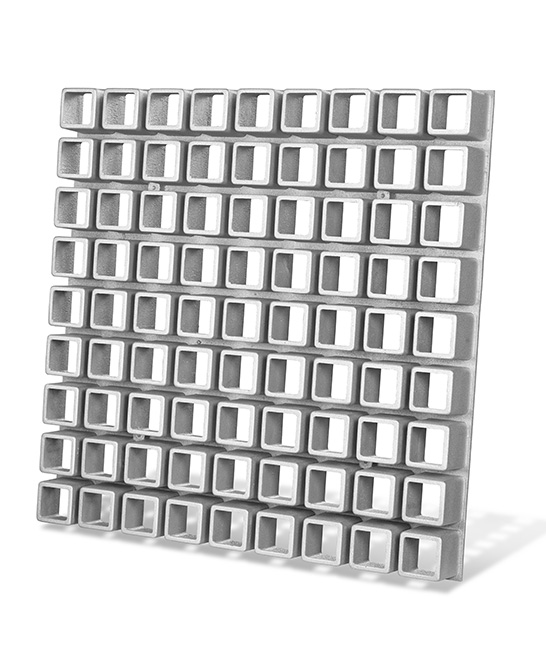

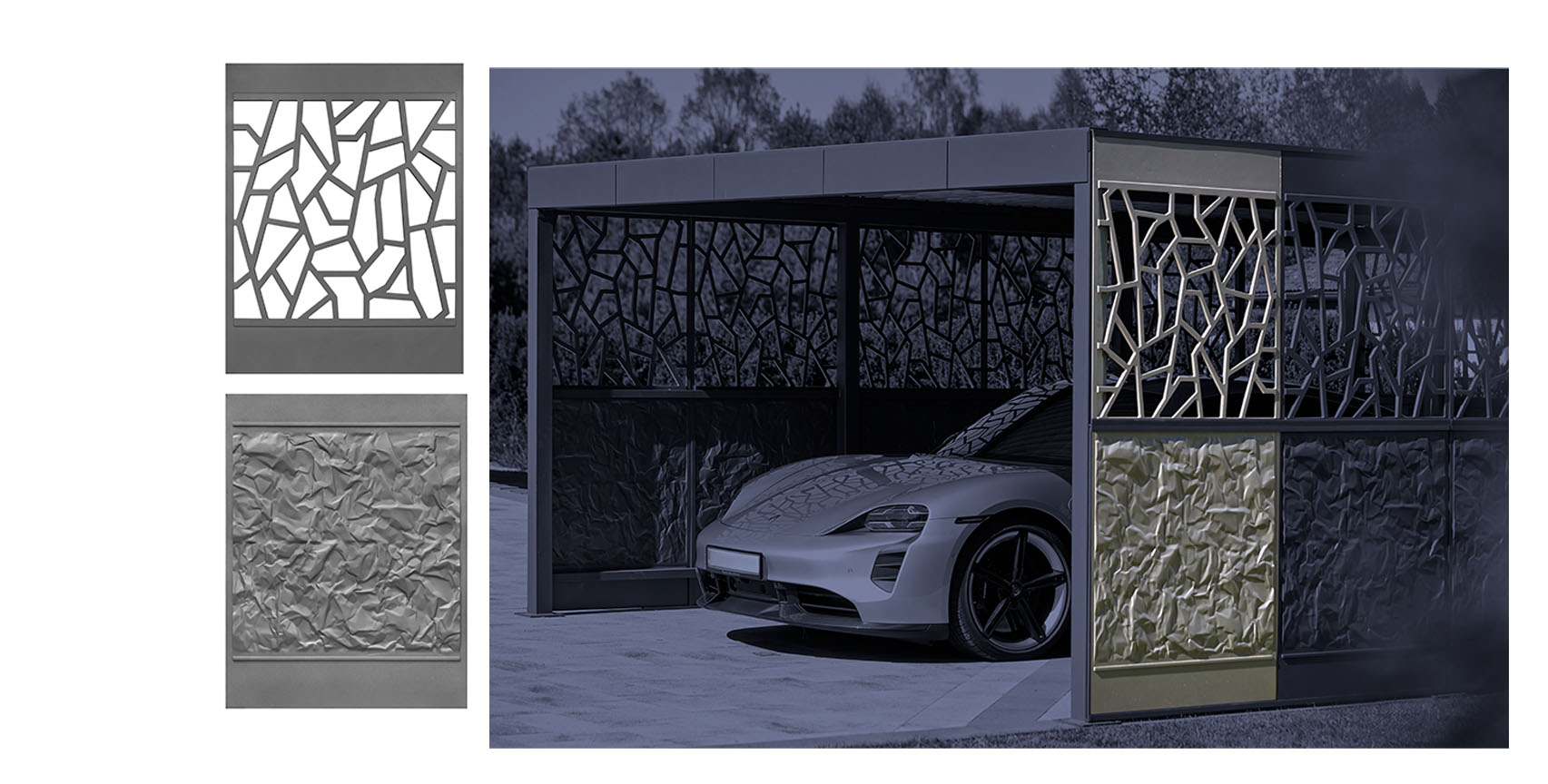

Typical application areas for aluminum include windows, doors, façades, roofs, and walls. In architecture, aluminum is generally used in sheet and profile form. We offer our customers individual solutions in aluminum casting for realizing their projects. Aluminum casting breaks previous limits in design and aesthetics through its nearly unlimited creative freedom.

Characteristics

Characteristics

What are the advantageous properties of aluminum casting 's in architecture?

- Corrosion resistance reduces maintenance effort

- Low density / weight allows the use of lightweight structures

- Design freedom enables unique design

Examples of aluminum casting's

in architecture

Examples

- Interior design panels

- Fences

- Facades

- Carports

Which casting processes does Thoni

Alutec offer for architecture?

Casting processes

- Sand casting with 3D sand printing process (prototypes)

- Sand casting using air setting resin moulding process's (no-bake process)

- Sand casting with automatic molding line

- Gravity die casting

- Low-pressure die casting

- Low-pressure sand mould casting technology

Got any questions? Or need advice?

Use the form or contact us