-AIR

Lightweight

Construction

für for light air

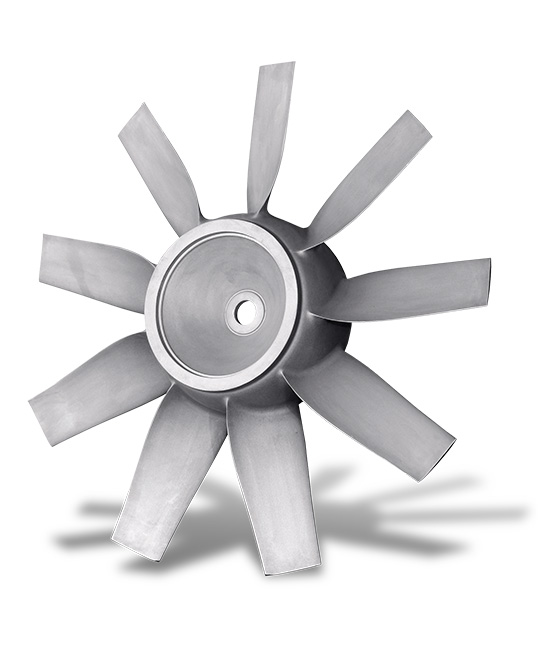

Fans made of steel are about twice as heavy as those made of aluminum. It takes more energy to drive a steel fan than an aluminum one. That’s why complete fans or impellers are increasingly being made of aluminum.

Fan Technology

Limitless

Limitless shaping

Limitless shaping

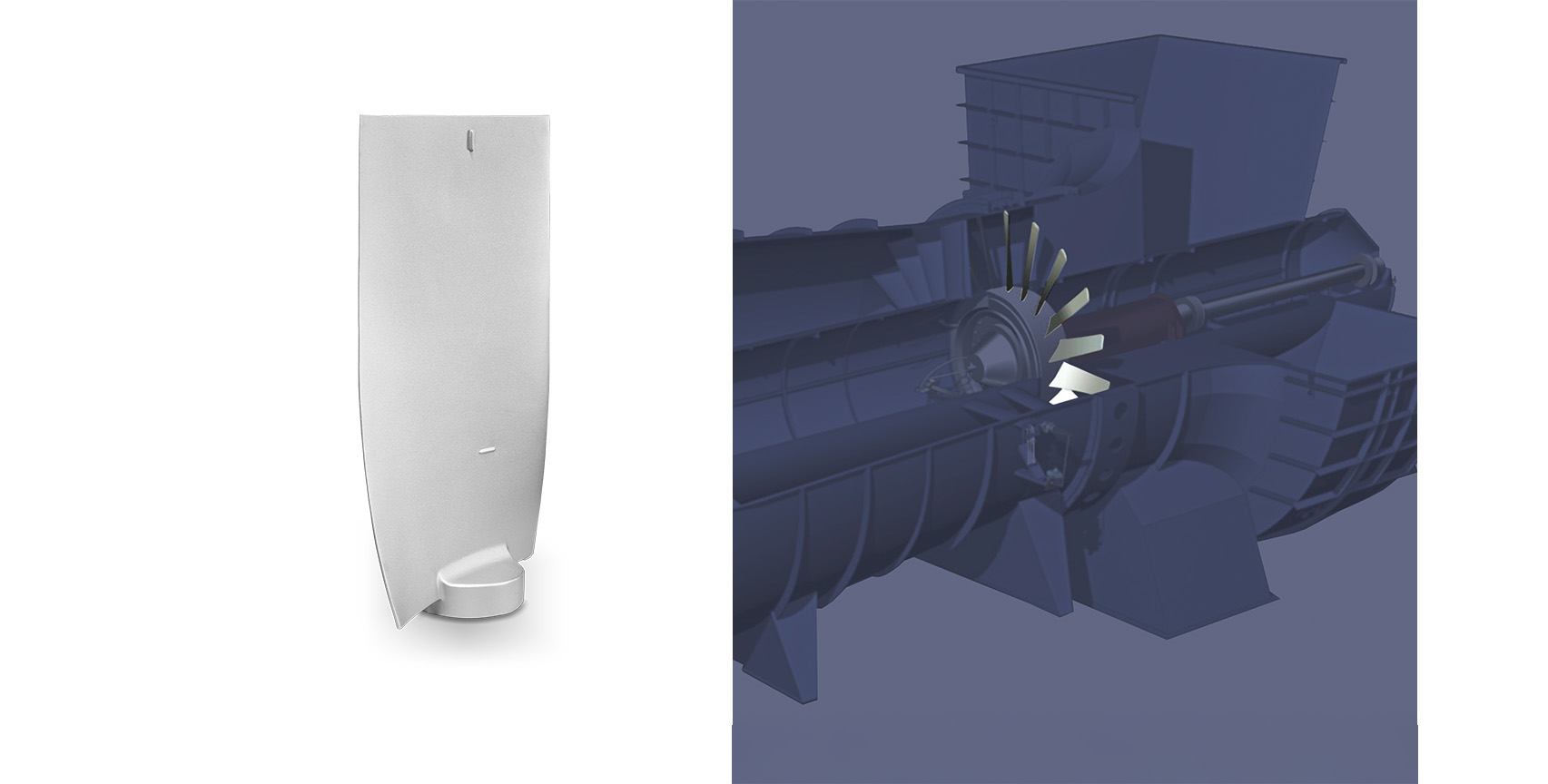

through casting technology

The design freedom offered by aluminum casting allows for ideal aerodynamics in fans. This makes them quiet and vibration-free during operation. Even in harsh environments, fans remain durable, as aluminum is corrosion-resistant.

Characteristics

Characteristics

What are the advantageous properties for aluminum casting's in fan technology?

- Corrosion resistance in polluted air environments

- Low density / weight allows for smaller drives

- Casting solutions are less prone to vibrations and quieter compared to welded construction assemblies

- Precise shaping reduces the effort of balancing

Examples of aluminum casting's

in fan technology

Examples

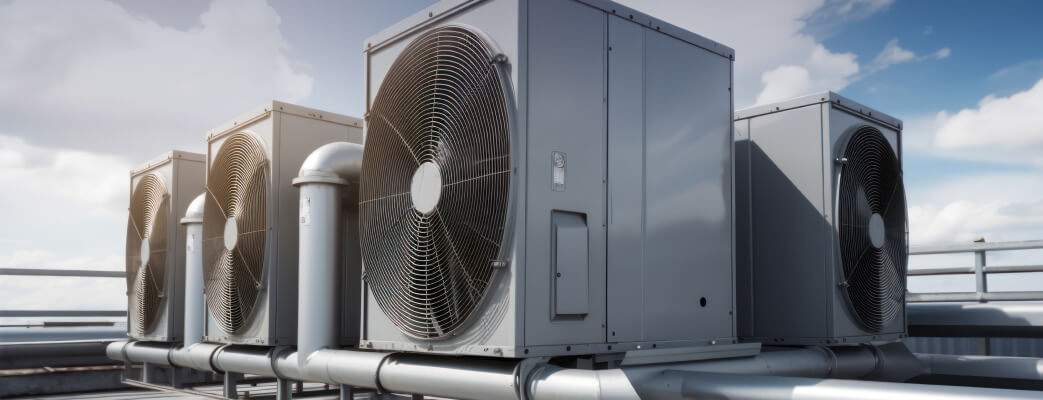

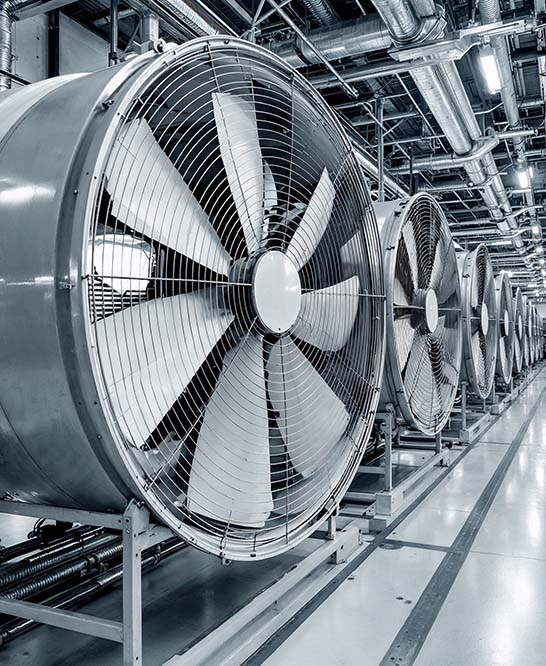

- Tunnels

- Rail transport

- Industrial halls

- Wood drying

Which casting processes does Thoni

Alutec offer for fan technology?

Casting processes

- Sand casting with 3D sand printing (prototypes)

- Sand casting using air setting resin moulding process's (no-bake process)

- Sand casting with automatic moulding line

- Gravity die casting

- Low-pressure die casting

- Low-pressure sand mould casting technology

Got any questions? Or need advice?

Use the form or contact us