Use of aluminum cast

components

Aluminum casting proves to be a key player in the oil and gas industry. Explosion-proof housings for control units on drilling platforms and in mining ensure safe operation. A spark, which could have fatal consequences in such environments, is ruled out. In addition, corrosion resistance ensures significantly reduced maintenance requirements at these often remote locations.

Oil and Gas

Certified Safety

Certified Safety

Adapted to the area of application and the legal requirements of each location, Thoni Alutec offers certified components made of aluminum casting. Certifications relate to processes, employees, and equipment in order to issue the necessary certifications for the final product.

Characteristics

Characteristics

What are the advantageous properties of aluminum casting's in the oil and gas industry?

- Aluminum casting's from Thoni Alutec are oil- and gas-tight

- No sparking

- Corrosion resistance is especially important in the offshore sector

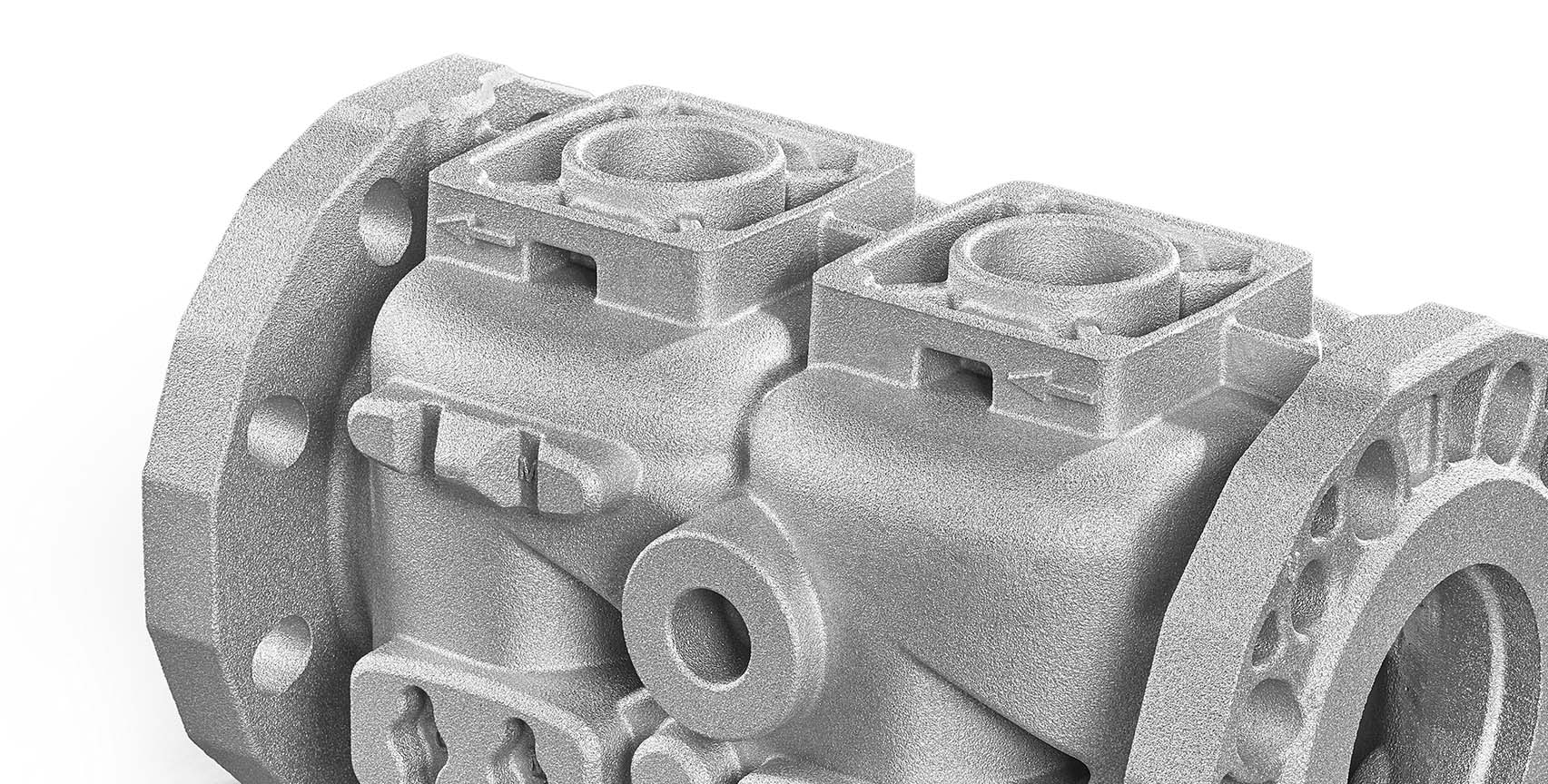

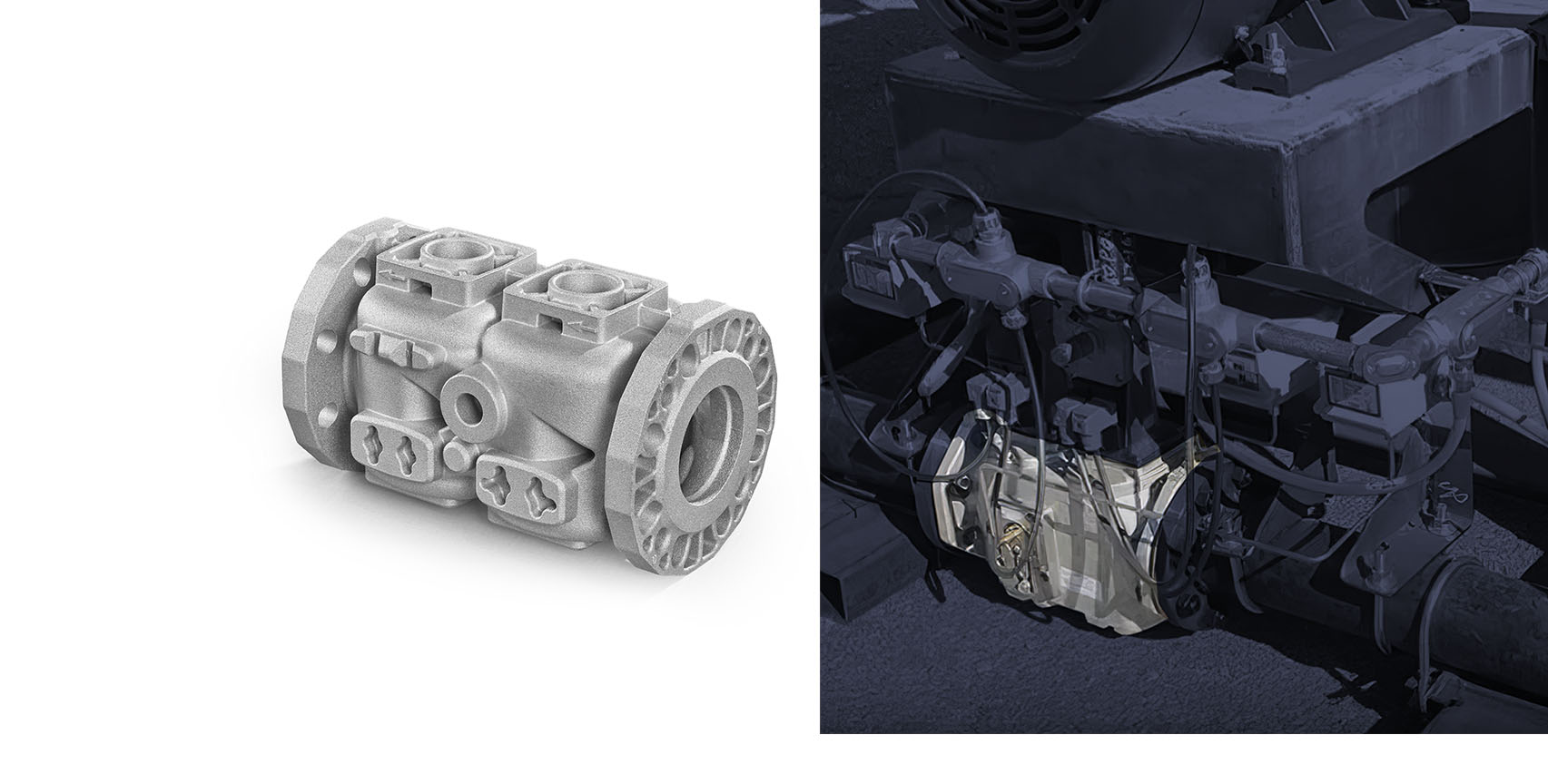

Examples of aluminum casting

in the oil and gas industry

Examples

- Marine

- Offshore lighting

- Control cabinets

- Rims for rail vehicles in underground mining

- Valve housings

Which casting processes does Thoni

Alutec offer for the oil and gas industry?

Casting processes

- Sand casting with 3D sand printing (prototypes)

- Sand casting using air setting resin moulding process's (no-bake process)

- Sand casting with automatic moulding line

- Gravity die casting

- Low-pressure die casting

- Low-pressure sand mould casting technology

Got any questions? Or need advice?

Use the form or contact us