Efficiency

Economic

Efficiency

In rail transport, it all comes down to efficiency. Aluminium casting provides lightweight and robust solutions for trams, subways and even high-speed trains. Applications can be found throughout the entire car body and bogie.

Rail transport

Weight savings

Every kilogram saved pays for the train

Aluminium is a multi-talent with many excellent properties, especially in rail vehicle construction. Rail vehicles are designed for a long service life of at least 30 years. Every kilogram saved during that time results in significant cost savings in track usage fees.

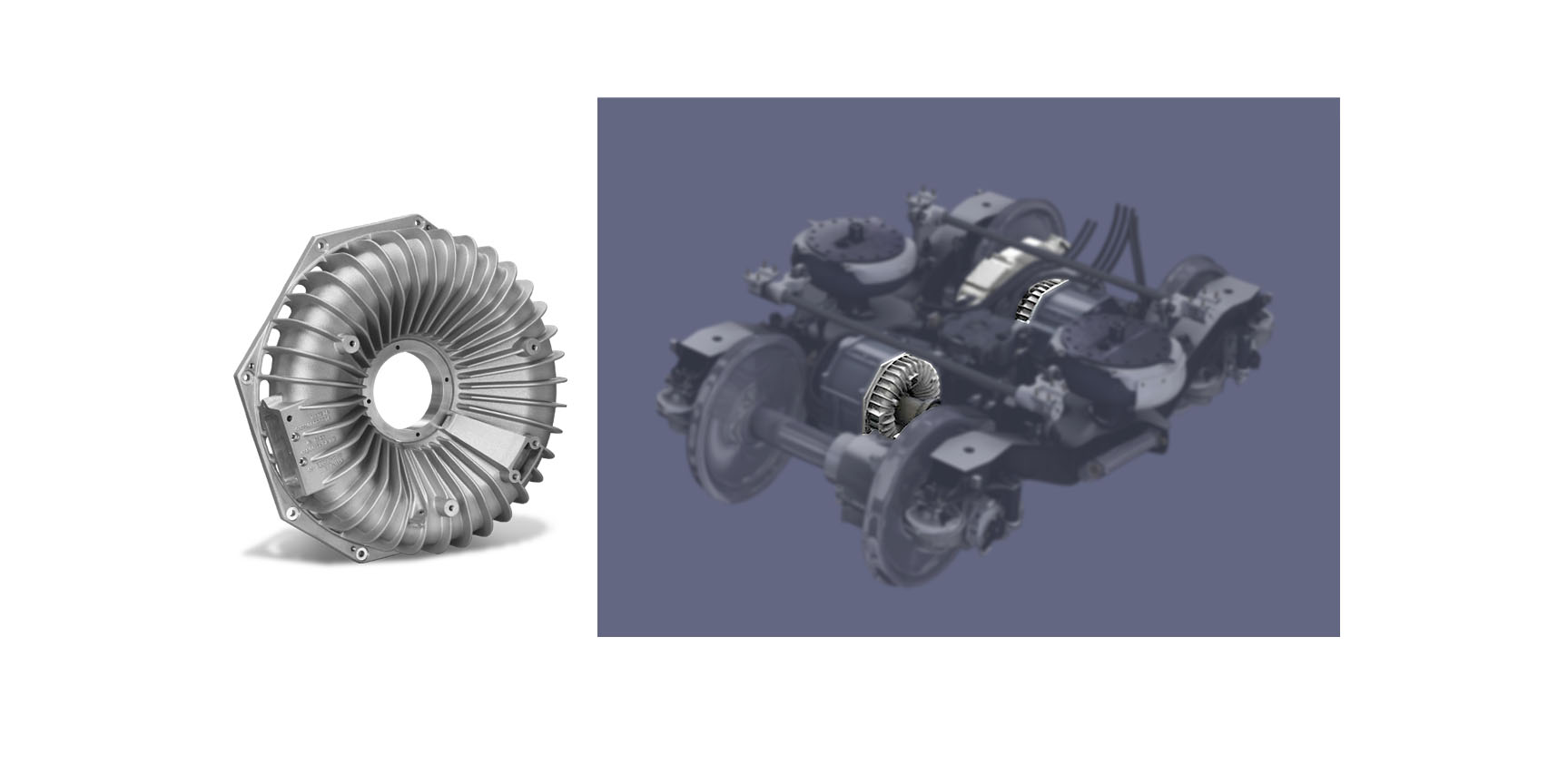

Parts in the bogie and side frames are commonly made of aluminium. Typical components from aluminium sand casting include axle gearboxes, bearing shields or fans. This includes sidewalls, roof and floor plates, and wheel discs.

Characteristics

Characteristics

What properties make aluminium casting suitable for rail transport?

- Even at very low temperatures, aluminium does not lose strength

- Aluminium is corrosion-resistant for use in aggressive environments

- Thanks to aluminium casting, the robot’s shape is ideally adapted to load requirements calculated by FEM during the design phase

Examples of aluminium castings

for use in rail transport

Examples

- Axle gearboxes

- Braking systems

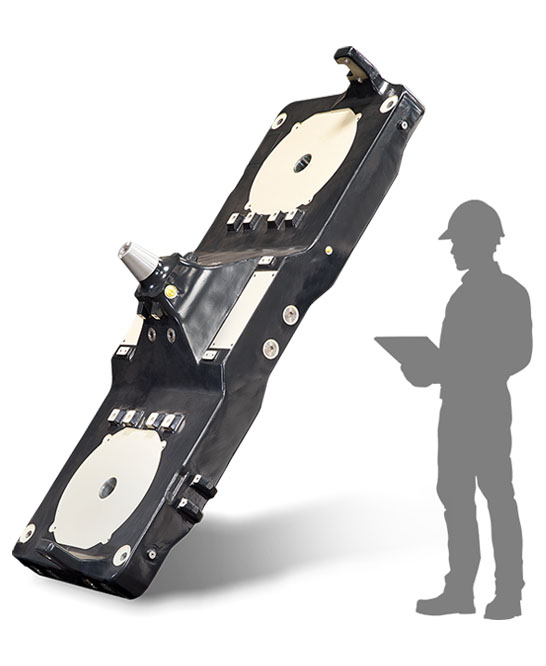

- Crash protection

- Crossmembers

- Front-end modules

casting processes Thoni-Alutec

offers for rail transport

Casting processes

- Sandguss mit 3D Sanddruck Verfahren (Prototypen)

- Sand casting using chemically bonded moulding processes (no-bake process)

- Sand casting on automated moulding lines

- Gravity die casting

- Low-pressure die casting

- Low-pressure sand mould casting

Got any questions? Or need advice?

Use the form or contact us