Economical and

more advantageous

Thoni Alutec has gained extensive experience in the vacuum industry through numerous projects involving aluminum cast components. Our cast parts are tested and certified for vacuum tightness according to customer specifications. We convert existing components made of rolled material into economically more advantageous casting solutions.

Vacuum Industry

Efficiency

Efficiency in application

Efficiency in application

and procurement

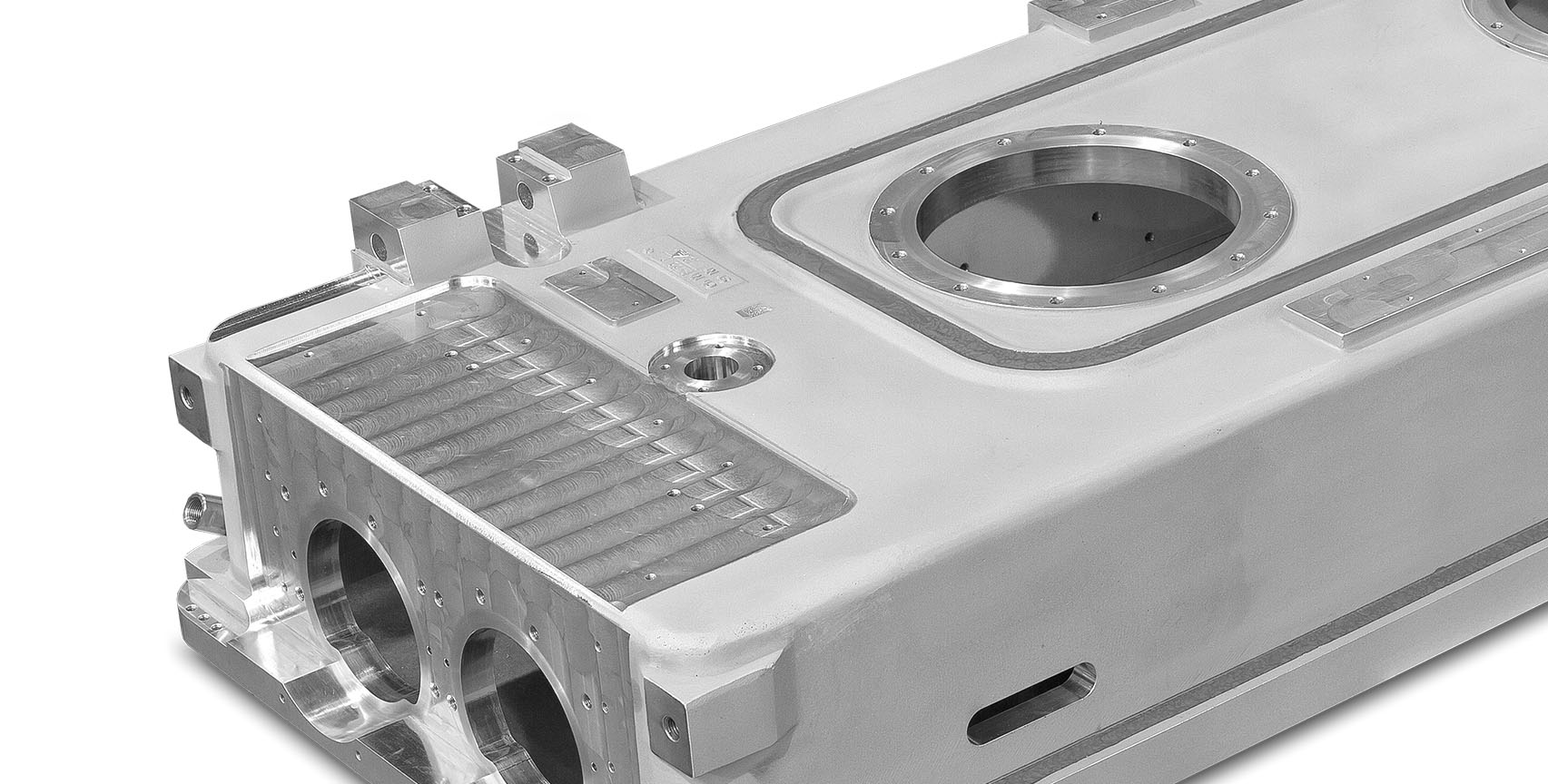

Since vacuum generation produces heat, the use of aluminum casting with integrated cooling fins ensures optimal heat dissipation. Housings made of stainless steel can often be manufactured more cost-effectively from aluminum due to its corrosion resistance. The same requirements apply to cast components for the semiconductor industry.

Characteristics

Characteristics

What are the advantageous properties for aluminum casting's in the vacuum industry?

- Corrosion resistant

- Suitable for use in cleanrooms

- High thermal conductivity

- Vacuum tight

Examples of aluminum casting's

in the vacuum industry

Examples

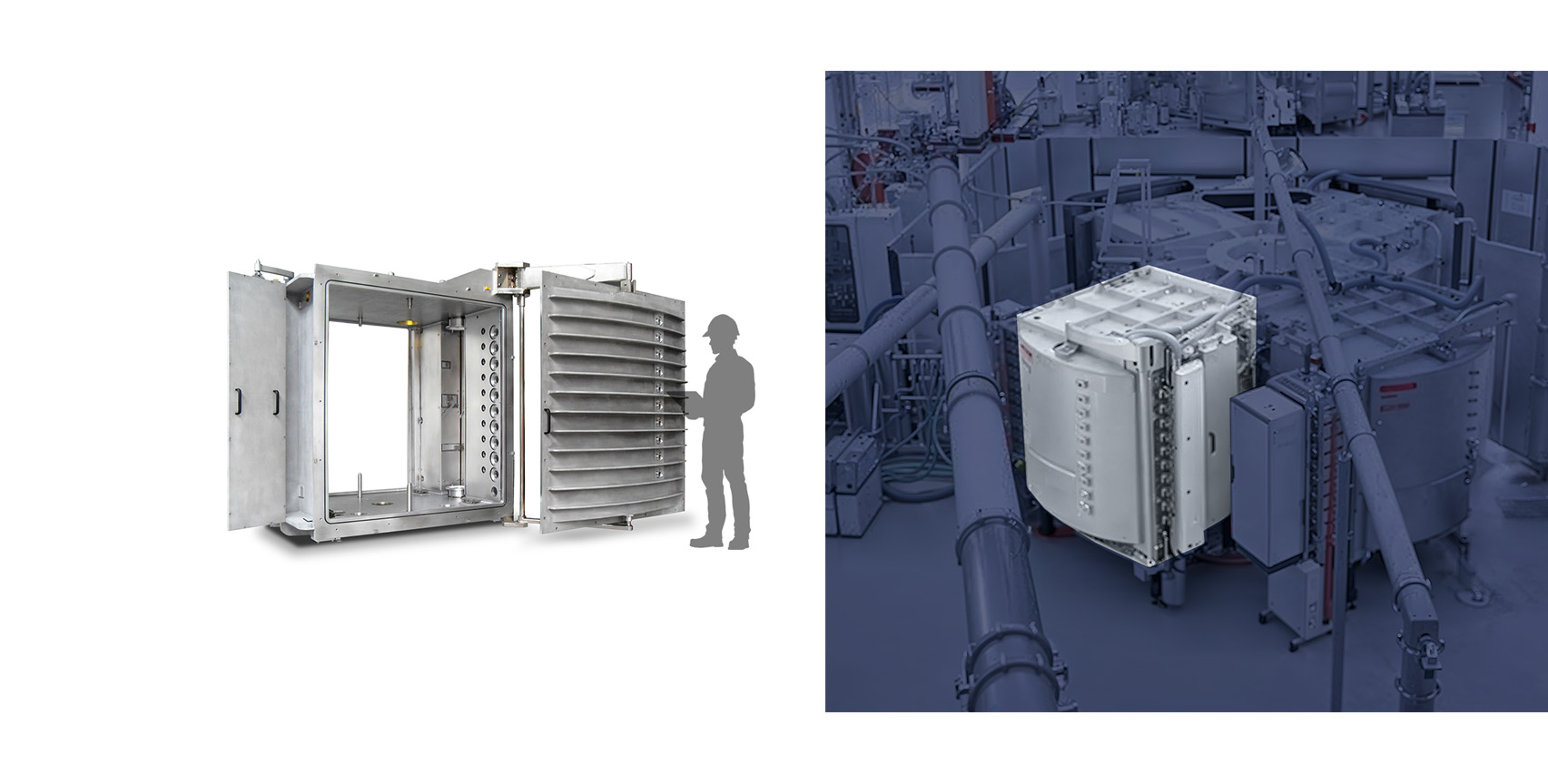

- Vacuum pumps

- Vacuum chambers

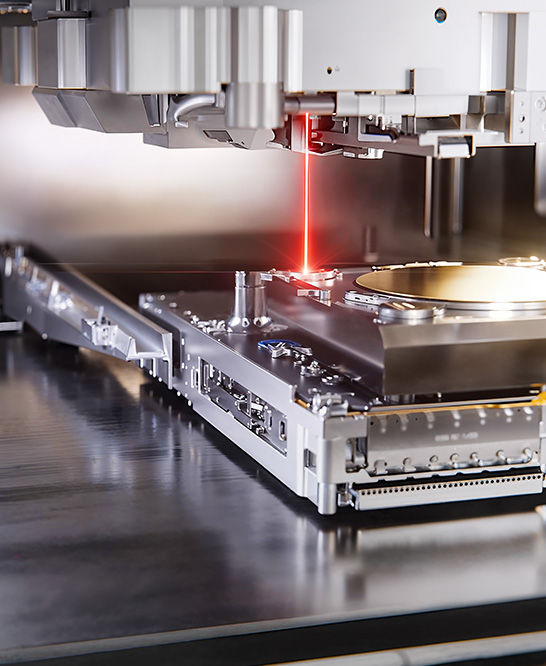

- System components for the semiconductor industry

- Lock chambers

Which casting processes does Thoni Alutec offer for the vacuum industry components?

Casting processes- Sand casting with 3D sand printing (prototypes)

- Sand casting using air setting resin molding process's (no-bake process)

- Sand casting with automatic moulding line

- Gravity die casting

- Low-pressure die casting

- Low-pressure sand mould casting technology

Got any questions? Or need advice?

Use the form or contact us