Many highly specialized departments

Casting production at Thoni Alutec includes many highly specialized departments. Enclosed is an overview of our broad capabilities and processes. Just like the processes, the customer industries are very diverse. Customers from the medical, rail, mechanical engineering, electromechanics, and energy sectors are just some examples from our portfolio.

Foundry

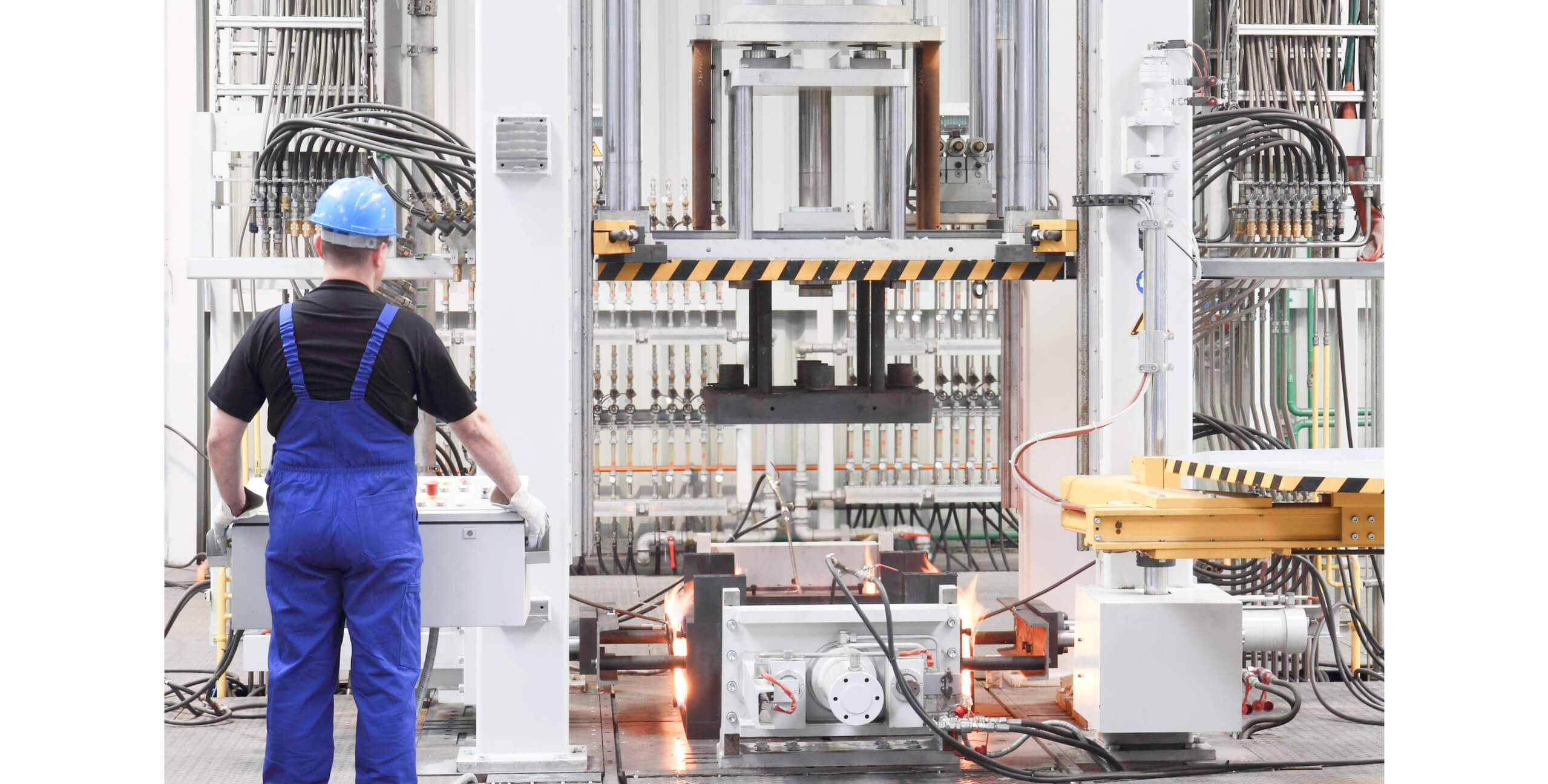

The heart and origin of our production is our foundry.

Our casting processesWe are a team of dedicated professionals committed to delivering aluminium castings of the highest quality. With decades of experience in the foundry sector, we have established ourselves as a reliable and trusted partner for all aluminium casting needs.

Thanks to our advanced facilities and state-of-the-art technology, we offer a wide range of casting services in sand casting, gravity die casting, and low-pressure casting. This allows us to tailor our services to the individual requirements of each customer.

Heat treatment

Maximum mechanical properties in aluminium casting through controlled heat treatment.

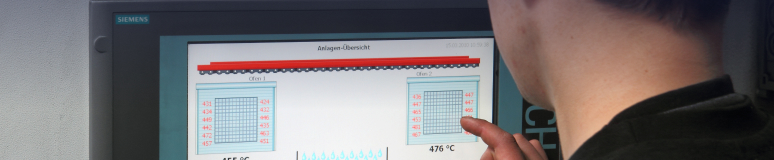

Our fully automated heat treatment systems are certified to ISO and NADCAP standards. This means we meet the requirements of all industries that use our castings. The key to our effective heat treatment lies in decades of experience. To fully exploit the potential of our aluminium alloys, parameters are adapted to the specific casting. In addition to time and temperature, proper storage of the parts in the oven is essential.

To minimize distortion of hot castings during quenching, special fixtures often need to be constructed.

In addition to the requirements of EN 1706 or other international standards, we adjust parameters depending on customer requirements. This allows the individual mechanical values to be precisely influenced.

CNC machining

Aluminium castings precisely machined with up to 6 axes.

Our processesOur in-house machining department consists of various types of CNC machines and is adapted to the current range of castings. As a customer-oriented foundry, we continue to expand this department based on demand.

Milling, drilling, and turning our castings is an essential part of our supply chain.

Machining aluminium castings requires a certain level of expertise, which not every machining company possesses. The alloy components and internal stresses of the castings must be considered when selecting tools, process parameters, and clamping devices. Close coordination between the foundry and mechanical processing allows for ideal alignment in the production of the final product.

Surface coating

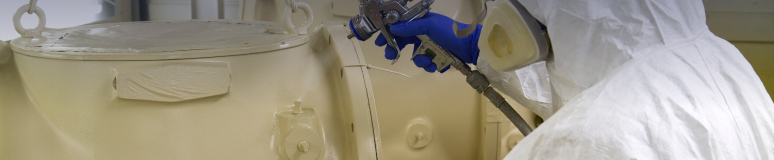

Paint, powder, or electroplating as coating for our castings

Our processesAnother step in our supply chain is the application of wet and powder coatings.

Paints serve to protect components or provide purely visual enhancement. Copper or silver plating also improves the electrical conductivity of contact surfaces.

As with all processes, this department complies with international standards and customer-specific approvals. We only source raw materials from approved and certified subcontractors.

Weld joining

Joining aluminium castings and profiles through various welding methods.

Our processesWe weld casting/casting or casting/profile connections manually, semi-automatically, or fully automatically by robot. The following welding methods are used:

- TIG

- MIG

- FSW (Friction Stir Welding)

The appropriate method is chosen based on customer requirements.

Producing a flawless weld requires that the weld edge on the casting consists of absolutely defect-free material. The quality of the weld is verified through crack testing or X-ray inspection.

R&D

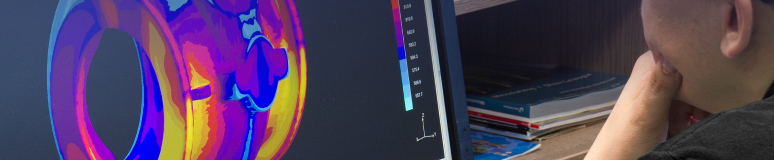

Our R&D department continuously researches new processes and materials. It also supports the implementation of new casting designs.

Our R&D department continuously researches new processes and materials. It also supports the implementation of new casting designs.

We support you from the initial idea to the finished, ready-to-install component. All required steps are integrated in-house and interconnected. This allows all supply chain aspects to be reviewed and aligned with your designated contact.

The team initially focuses on a casting-friendly design, complying with symmetry and technical requirements of the parts. For components under high mechanical stress, we evaluate the finite element analysis (FEA) and then incorporate our design suggestions into your 3D model.

In addition to achieving mechanical strength, the main focus is on maximum possible weight reduction. The goal of optimization is to design the best possible balance of stability, lightness, and cost-efficiency.

In the final stage of development, the casting process is simulated and checked for feasibility using our MAGMA software in consultation with the foundry.

In parallel, our machining specialists define which areas are practical and feasible for machining.

Toolmaking

In our tool shop, we design and manufacture models, dies, and fixtures for various departments. Our in-house tool shop serves as the interface between casting and tool production, ensuring the closest possible integration. Staff from different departments can meet quickly and exchange feedback on the product and process.

Customer change requests can be implemented on-site in a short time. Additional capacities at external partners are coordinated by our team on a project basis.

Designing and manufacturing casting tools enables us to develop and test new tool technologies. This allows us to continually offer the most suitable casting technologies for each application.

Our in-house manufacturing capabilities ensure that tools and equipment meet our internal requirements and quality standards. This clearly contributes to improved quality of the resulting castings.