tools

Custom-made tools made of wood, synthetic resins, aluminum, or steel form the foundation for our production.

Our in-house toolmaking department is a central component of our production, providing our own designed tools and fixtures for the manufacture of aluminum castings. Our designers, in coordination with the respective production department, create 3D data and 2D drawings for tool production. We utilize a wide variety of CAD/CAM systems to process data from customers around the world.

Model making for the sand foundry

In model making, ancient tradition meets modern technology. Where models were once crafted by hand, we now use 5-axis milling machines that mill the models from block material. We design and manufacture models used for sand casting molds. Depending on the required service life of the models, we use a variety of materials. This also creates models for prototypes or small-batch production. The in-house model shop also carries out maintenance and any index changes to existing models.

Mould construction for the die foundry

We design and manufacture tools from special steel alloys for production in gravity or low-pressure dies. The hot-work tool steel we use is suitable for the high thermal and mechanical stresses encountered during production. Our heaviest die-cast components weigh over 200 kg. Sand cores or stainless steel tubes are cast into them to create complex internal contours. Regular inspection and maintenance of our dies is essential to ensure their service life.

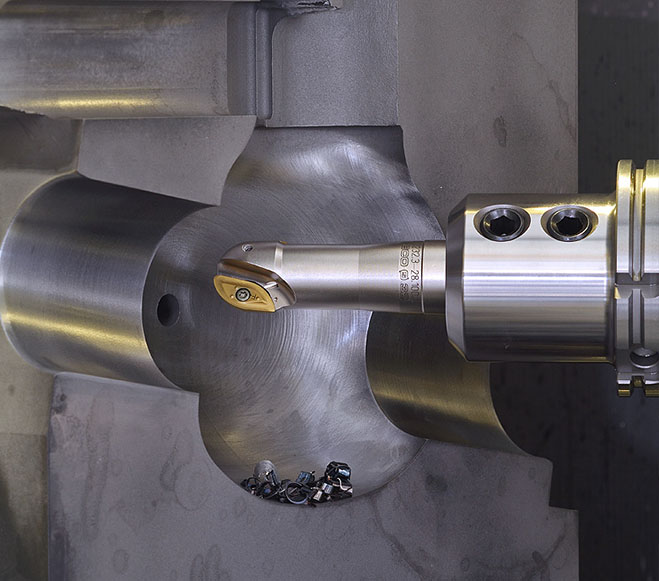

Fixture construction for mechanical processing

Our fixture construction department is responsible for the design and manufacture of special fixtures used during the machining of castings. All fixtures are designed and engineered in consultation with the foundry to suit the raw castings. The individual components are then manufactured and assembled internally or externally. After successful measurement testing, the fixtures are released for initial sample production.

Got any questions? Or need advice?

Use the form or contact us